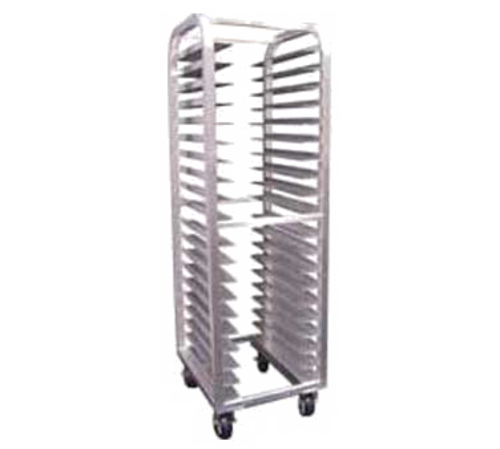

Stop compromising workflow for inadequate storage. This full-height mobile pan rack delivers organized transport capacity and consistent spacing to streamline production lines in institutional kitchens and high-volume operations. Designed for repeated daily use, the aluminum frame resists corrosion while remaining lightweight for easier repositioning and loading.

LongDescription#@#NA#@@#Cleaning Instructions#@#Wipe aluminum frame and pan supports with mild detergent and warm water; rinse and dry to prevent oxidation. Sanitize high-touch zones like handles and caster stems with EPA-listed disinfectant per label dwell time. Inspect casters and welds weekly; tighten fasteners and remove food debris beneath shelves to deter pests. Regular cleaning prevents cross-contamination, supports health-code compliance, and preserves rack appearance and service life.#@@#Additional Info#@#Winholt’s AL-1820BKD-HD mobile pan rack is 21" W x 26" D x 69" H, holding twenty 18" x 26" pans with 3" OC spacing. It features durable, NSF-certified aluminum construction and 5" swivel casters for easy transport, weighing 43 pounds.#@@#General Info#@#Description #@#

Stop compromising workflow for inadequate storage. This full-height mobile pan rack delivers organized transport capacity and consistent spacing to streamline production lines in institutional kitchens and high-volume operations. Designed for repeated daily use, the aluminum frame resists corrosion while remaining lightweight for easier repositioning and loading.

#@@# Aluminum Construction#@#

Aluminum construction provides a high strength-to-weight ratio that reduces total unit weight while maintaining structural rigidity under load. Operators gain corrosion resistance in humid or wet back-of-house environments and lower maintenance compared with painted steel.

#@@# End Loading#@#

End loading access allows staff to slide pans in and out from the short side, reducing aisle clearance needs and accelerating staging during peak service. Chefs benefit from faster turnover when moving racks between prep, bake, and service stations.

#@@# Open Sides#@#

Open sides enable visual inventory checks and rapid pan retrieval without rotating or repositioning the rack. Supervisors increase throughput by minimizing interruptions to line cooks during shift changes.

#@@# Pan Capacity#@#

The rack accepts up to 20 standard 18 inch by 26 inch pans with 3 inches on-center spacing, yielding controlled air circulation between pans for consistent cooling or holding. Managers can stage multiple product batches on a single rack to balance production runs across ovens and holding units.

#@@# All Welded Supports#@#

All welded angle pan supports create a fixed, secure framework that resists loosening under repetitive loading cycles and transportation. Maintenance teams observe fewer fastener failures and reduced downtime compared with assemblies that rely on mechanical clips.

#@@# Mobile Casters#@#

Five inch polyurethane swivel stem casters provide smooth maneuvering and resilient floor protection over tile and concrete surfaces.

#@@#Delivery Details#@#

• Please ensure to handle the product with utmost care.

• Check if the product you have received has all the essential parts and accessories.

• Make sure to examine the product for damage before signing the delivery receipt.

• Contact customer service for delivery concerns.

• Delivery times may vary based on location.#@@#deliverynotes#@#NA#@@#Maintenance Guide#@#Inspect welds and cross braces weekly; tighten loose fasteners and address corrosion with aluminum cleaner to preserve integrity. Rotate pan loads to balance wear and prevent deformation. Lubricate 5" polyurethane swivel stem casters monthly with light machine oil and ensure caster nuts are torqued. Clean interior channels and pan supports after each shift with mild detergent and hot water; rinse and dry to prevent residue. Store rack indoors when not in use.