Handle high-volume pour lines without compromising control or temperature. This draft wine dispenser supports continuous service with regulated cooling, precise filling, and a compact footprint that fits behind most bars. Designed for commercial use since 1998, the unit delivers consistent performance and serviceability for restaurants, hotels, campuses, and hospitals.

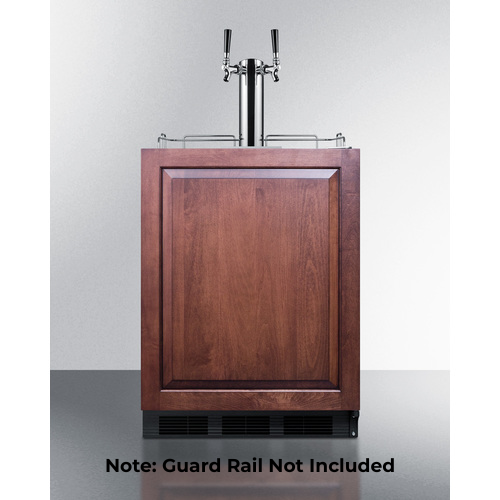

LongDescription#@#NA#@@#Cleaning Instructions#@#Unplug the unit and remove kegs or bottles. Wipe interior with mild soap and warm water; rinse and dry. Clean condenser coils every 3 months to maintain cooling efficiency and lower energy use. Remove grease and residue from dispensing heads and hoses with manufacturer-approved cleaner to prevent contamination. Inspect door seals and replace worn gaskets. Keep vents clear to avoid overheating and reduce fire risk. Document each cleaning for CSA and health inspections.#@@#Additional Info#@#Summit’s SBC58BLBIADAIFWKDTWIN 24" black draft wine dispenser operates on 115 volts with R-600a refrigerant, 1.2 amps, and 60 Hz. It delivers a +34° to +43°F temperature range, self-contained refrigeration, and weighs 110 pounds.#@@#General Info#@#Description #@#

Handle high-volume pour lines without compromising control or temperature. This draft wine dispenser supports continuous service with regulated cooling, precise filling, and a compact footprint that fits behind most bars. Designed for commercial use since 1998, the unit delivers consistent performance and serviceability for restaurants, hotels, campuses, and hospitals.

#@@# Temperature Control#@#

Set temperatures between +34° and +43°F to preserve flavor and extend open-keg life. Technicians access simple mechanical controls for rapid adjustments, ensuring stable cellar conditions during busy service periods.

#@@# Self-Contained Cooling#@#

Built with self-contained refrigeration and R-600a refrigerant, the dispenser operates without external compressors or remote connections. Service teams appreciate reduced installation time and straightforward maintenance procedures.

#@@# Dispensing Capacity#@#

Support multiple kegs and continuous flow with a layout optimized for simultaneous pours. Operators achieve steady output while maintaining accurate fill volumes and minimizing foam during peak demand.

#@@# Electrical Compatibility#@#

Operate on 115 volts at 1.2 amps and 60 hertz, single-phase power, enabling plug-in installation in typical commercial back bars. Facilities staff benefit from predictable electrical load and simplified integration into existing circuits.

#@@# Durable Exterior#@#

The all-black metal finish resists scuffs and integrates seamlessly with professional bar stations. Cleaning crews find flat surfaces and accessible panels reduce time required for routine sanitation.

#@@# Certifications and Safety#@#

Meet UL, CSA, ETL sanitation, and NSF standards for commercial refrigeration and dispensing equipment. Purchasing managers gain documented regulatory compliance for foodservice environments and reduced inspection friction.

#@@#Delivery Details#@#

• Please ensure to handle the product with utmost care.

• Check if the product you have received has all the essential parts and accessories.

• Make sure to examine the product for damage before signing the delivery receipt.

• Contact customer service for delivery concerns.

• Delivery times may vary based on location.#@@#deliverynotes#@#Delivery requires ground-level access. Inspect the unit upon arrival for any damage and contact customer service within 48 hours for assistance.#@@#Maintenance Guide#@#Maintain the Summit SBC58BLBIADAIFWKDTWIN by defrosting and cleaning interior surfaces monthly using a mild detergent and a soft cloth. Inspect door gaskets weekly for cracks and replace if leakage occurs. Sanitize dispensing lines per manufacturer intervals and purge with food-grade solution after each keg change. Clean condenser coils quarterly to preserve heat transfer. Verify temperature stays within +34° to +43°F and log readings daily to ensure compliance and consistent operation.