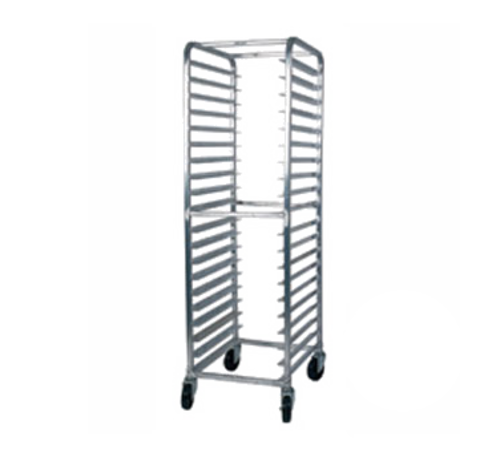

Stop sacrificing durability for mobility. This aluminum mobile pan rack delivers organized transport and high-capacity storage without adding excess weight, enabling fast turnover in high-volume kitchens while resisting corrosion and daily wear. Designed for commercial operations that require predictable handling and sanitary performance, this unit combines welded construction with generous pan capacity to streamline food prep and service.

LongDescription#@#NA#@@#Cleaning Instructions#@#Wipe rack rails and solid top with a mild detergent and warm water; rinse and dry immediately to prevent corrosion. Sanitize high-touch zones like handles, caster stems, and pan runners with a commercial sanitizer per label dwell time. Inspect casters weekly; tighten hardware and clear debris under shelves to deter pests. Clean prevents contamination transfer, supports health-code compliance, and preserves finish and function for long service life.#@@#Additional Info#@#Winholt's AL-1812BP-XB-ST mobile pan rack holds 12 full-size sheet pans, has all-welded aluminum construction, a solid top, and four 5" casters. It measures 69.75" high by 26" wide by 21" deep and weighs 48 pounds.#@@#General Info#@#Description #@#

Stop sacrificing durability for mobility. This aluminum mobile pan rack delivers organized transport and high-capacity storage without adding excess weight, enabling fast turnover in high-volume kitchens while resisting corrosion and daily wear. Designed for commercial operations that require predictable handling and sanitary performance, this unit combines welded construction with generous pan capacity to streamline food prep and service.

#@@# Solid Top#@#

Full-height solid top provides a rigid cover and serves as a temporary staging surface for packaged goods or small equipment. Engineers built the top into the welded frame to maintain structural integrity while handling routine kitchen loads.

#@@# Open Sides#@#

Open-side design allows unobstructed access to pans from both faces, accelerating loading and unloading during peak service. Chefs and line staff can reach pans quickly without shifting the rack, reducing service time and labor motions.

#@@# High Capacity#@#

The rack accommodates up to 12 half-size sheet pans in a full-height configuration, supporting continuous production and holding multiple product lines simultaneously. Operators can stage completed trays and empty racks without frequent trips to storage.

#@@# Reinforced Sides#@#

Heavy-duty reinforced sides absorb cross-traffic impacts and prevent deformation under daily use in busy back-of-house environments. Fabricators reinforce the verticals to preserve runner alignment and maintain consistent pan fit over the product lifecycle.

#@@# Durable Construction#@#

All-welded aluminum construction yields a lightweight unit that resists rust and reduces total mass compared with steel alternatives, improving maneuverability and lowering caster wear. Technicians fabricate the frame to meet commercial demands while keeping the empty weight manageable.

#@@# Smooth Casters#@#

Four 5-inch polyurethane plate casters deliver smooth rolling over typical kitchen flooring and minimize vibration transfer to stored pans.

#@@#Delivery Details#@#

• Please ensure to handle the product with utmost care.

• Check if the product you have received has all the essential parts and accessories.

• Make sure to examine the product for damage before signing the delivery receipt.

• Contact customer service for delivery concerns.

• Delivery times may vary based on location.#@@#deliverynotes#@#NA#@@#Maintenance Guide#@#Inspect wheels weekly and lubricate caster bearings with food-grade lubricant to maintain rotation and prevent binding. Tighten all fasteners monthly and verify 5" polyurethane plate casters remain secure. Clean aluminum surfaces after each shift using mild detergent and warm water; rinse and dry to prevent residue. Check 1-1/2" angle runners for deformation and replace damaged runners immediately. Store rack indoors to avoid corrosion and preserve NSF compliance.