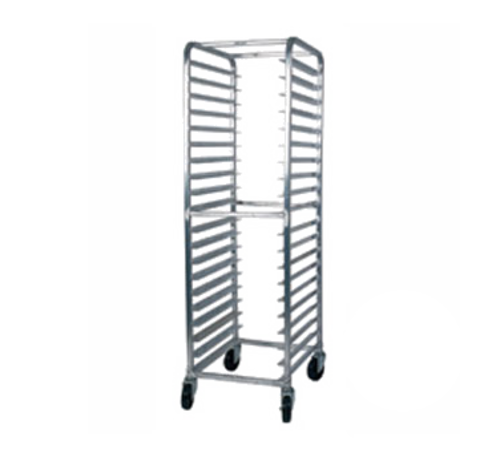

Stop trading durability for portability. This aluminum full-height mobile pan rack offers robust transport and storage for high-volume kitchens while minimizing corrosion and maintenance needs. Designed for end loading and heavy daily use, the unit supports organized workflow and rapid turnover in busy culinary operations.

LongDescription#@#NA#@@#Cleaning Instructions#@#Clean rack surfaces after each shift to prevent contamination of clean items and hands. Use a mild detergent and warm water; scrub runners and open sides with a soft brush, then rinse and dry. Sanitize high-touch zones like end frames and caster plates with an EPA-registered sanitizer per label contact time. Inspect casters and welds; tighten hardware as needed. Regular cleaning preserves appearance, reduces pests, and helps meet health code inspections.#@@#Additional Info#@#Winholt AL-1812BP-XB mobile full-height pan rack holds twelve 18" x 26" sheet pans on 1-1/2" angle runners. It features all-welded aluminum, reinforced sides, four 5" casters, NSF certified, 26" depth, 69.75" height, 35 pounds, made in USA.#@@#General Info#@#Description #@#

Stop trading durability for portability. This aluminum full-height mobile pan rack offers robust transport and storage for high-volume kitchens while minimizing corrosion and maintenance needs. Designed for end loading and heavy daily use, the unit supports organized workflow and rapid turnover in busy culinary operations.

#@@# "Aluminum Construction"#@#

Crafted from all-welded aluminum, the rack resists corrosion while reducing overall weight to 35 pounds, allowing staff to reposition units without mechanical assistance. The material delivers structural strength for continuous use and complies with NSF sanitation requirements.

#@@# "Full Height Design"#@#

The 69.75-inch tall frame maximizes vertical storage in a compact footprint, accommodating up to 12 pans to optimize space in tight kitchens. The tall profile enables stacked transport between prep and service zones while maintaining accessibility for loading and unloading.

#@@# "End Loading Access"#@#

End loading eliminates the need to reach along the sides, reducing handling time and improving ergonomics for operators. Teams achieve faster pan changes during peak periods, increasing throughput and lowering labor strain.

#@@# "Open Slide System"#@#

Open sides with 1-1/2-inch angle runners provide clear sight lines and rapid pan insertion for half-size 18" x 26" sheet pans. The open slide configuration facilitates airflow and quick visual inventory counts during service.

#@@# "Reinforced Side Panels"#@#

Reinforced heavy-duty side construction stabilizes the chassis under load and resists deformation during transport. Kitchens that move racks frequently will benefit from sustained alignment of slides and consistent pan fit.

#@@# "Mobility Casters"#@#

Four 5-inch polyurethane plate casters deliver smooth rolling across service corridors and resist flat spots, preserving maneuverability over tile or sealed concrete.

#@@#Delivery Details#@#

• Please ensure to handle the product with utmost care.

• Check if the product you have received has all the essential parts and accessories.

• Make sure to examine the product for damage before signing the delivery receipt.

• Contact customer service for delivery concerns.

• Delivery times may vary based on location.#@@#deliverynotes#@#NA#@@#Maintenance Guide#@#Inspect caster bearings weekly and tighten hardware to prevent wobble. Clean aluminum surfaces with a pH-neutral cleaner and soft brush, then rinse with clear water to avoid corrosion. Remove food particles from angle runners and sanitize with an NSF-approved sanitizer; allow racks to air dry before loading. Lubricate caster swivel points quarterly with food-safe lubricant. Verify weld integrity and replace damaged parts immediately.