Stop compromising uptime for cooling performance. This self-contained refrigerated frost top delivers consistent low temperatures and straightforward controls for high-throughput kitchens, supporting sheet pan workflows while minimizing maintenance interruptions. Operators will gain a reliable cold slab that integrates into counters and sustains product quality during service.

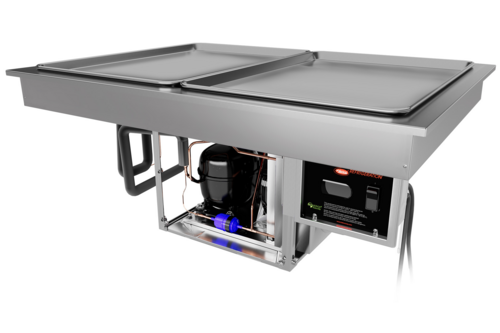

LongDescription#@#NA#@@#Cleaning Instructions#@#Unplug the unit and remove pans. Wipe interior and cold slab with a mild detergent and a soft cloth; rinse and dry thoroughly. Clean condenser coils every month using a brush or vacuum to remove dust and grease. Inspect door seals and replace if cracked. Defrost per manufacturer instructions and ensure R-290 components remain dry. Dispose of waste per CSA and local codes. Regular cleaning prevents contamination, reduces fire risk, lowers energy use, and extends equipment life.#@@#Additional Info#@#Hatco's FTBP-1 frost top measures 21.06" wide, uses 120 volts, R-290 refrigerant, and a 1/4 HP compressor. It offers self-contained refrigeration, auto-defrost, electronic temperature control, cULus certification, and is Made in USA for foodservice.#@@#General Info#@#Description #@#

Stop compromising uptime for cooling performance. This self-contained refrigerated frost top delivers consistent low temperatures and straightforward controls for high-throughput kitchens, supporting sheet pan workflows while minimizing maintenance interruptions. Operators will gain a reliable cold slab that integrates into counters and sustains product quality during service.

#@@# Drop-In Design#@#

Installers receive a unit sized 21.06 inches wide that fits standard drop-in cutouts, enabling fast retrofit into existing counters. Technicians will appreciate that the compact footprint simplifies integration without sacrificing usable slab area.

#@@# Self-Contained Cooling#@#

The refrigeration system runs on R-290 refrigerant with a 1/4 HP compressor, providing effective heat extraction while avoiding external condensing equipment. Maintenance crews perform service on a single, accessible assembly, reducing downtime compared with remote systems.

#@@# Adjustable Temperature#@#

Operators control slab temperature via an electronic adjustable thermostat that mounts to either side of the condensing unit or can run remotely up to 4 feet. Staff calibrate setpoints quickly to match product requirements, improving consistency across service periods.

#@@# Auto Defrost#@#

The unit includes automatic defrosting to prevent frost buildup and maintain thermal transfer efficiency. Kitchen teams spend less time on manual defrost cycles, preserving cooling performance during continuous operation.

#@@# Lighted Rocker Switch#@#

A clearly visible on/off rocker switch with integrated lighting allows staff to confirm unit status at a glance during busy shifts. Supervisors reduce misstarts and accidental power cycles by relying on the switch feedback.

#@@# Compliance And Build#@#

Manufacturers certify the unit to cULus standards and assemble it in the USA, assuring buyers of regulated safety and documented performance.

#@@#Delivery Details#@#

• Please ensure to handle the product with utmost care.

• Check if the product you have received has all the essential parts and accessories.

• Make sure to examine the product for damage before signing the delivery receipt.

• Contact customer service for delivery concerns.

• Delivery times may vary based on location.#@@#deliverynotes#@#NA#@@#Maintenance Guide#@#Inspect condenser coils weekly and remove dust with a soft brush to maintain heat transfer efficiency. Replace air filters monthly and verify door gaskets for compression; reseal or replace when gaps exceed 1/8 inch. Calibrate the electronic temperature control quarterly and document setpoints. Drain and clean the drip pan monthly to prevent microbial growth. Use only R-290–compatible service technicians for refrigerant work and follow CSA and cULus service guidelines.