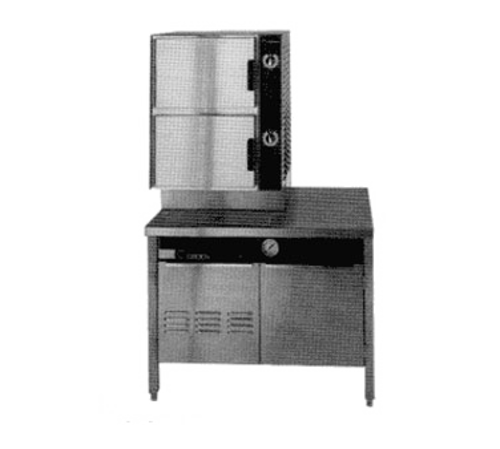

Engineered for continuous service and precise steam control, this electric HyPlus pressureless steamer delivers restaurant-grade throughput without sacrificing consistency. Designed for dual compartment production, it supports simultaneous steaming of large pan volumes and minimizes cycle time with robust 24,000-watt power and 208v electrical supply. Operators gain reliable, repeatable results with manual controls and a stainless interior that withstands daily use in high-traffic kitchens.

LongDescription#@#NA#@@#Cleaning Instructions#@#Unplug power and let steamer cool. Drain water and open compartments. Wipe chamber surfaces and gasket with mild detergent and a soft cloth. Remove pans and wash in warm, soapy water; rinse and dry. Clean exterior stainless steel with nonabrasive cleaner. Inspect and clean drain and dual water connections for deposits. Descale boiler per manufacturer schedule. Check seals and controls for wear. Regular cleaning prevents bacteria, reduces fire risk, lowers energy use, and avoids breakdowns.#@@#Additional Info#@#Groen HY-10SE-36 stainless steel HyPlus steamer has two compartments with five 12" x 20" x 2.5" pans each, 208 volts, 24,000 watts, 67 amps, 3-Ph operation, manual controls, dual water connection, and is cUL/UL/NSF certified.#@@#General Info#@#Description #@#

Engineered for continuous service and precise steam control, this electric HyPlus pressureless steamer delivers restaurant-grade throughput without sacrificing consistency. Designed for dual compartment production, it supports simultaneous steaming of large pan volumes and minimizes cycle time with robust 24,000-watt power and 208v electrical supply. Operators gain reliable, repeatable results with manual controls and a stainless interior that withstands daily use in high-traffic kitchens.

#@@# Stainless Construction#@#

Rigid stainless steel fabrication provides corrosion resistance and structural stability for floor model installation. Maintenance teams appreciate smooth interior surfaces that resist soil buildup and simplify daily sanitation in compliance with NSF standards.

#@@# Two Compartment Layout#@#

Two independently loaded compartments let staff steam different menu items simultaneously, reducing cross-flavor transfer and improving staging flexibility. Kitchens achieve higher yield by running staggered cycles that match service demands.

#@@# High Pan Capacity#@#

Each compartment accepts five 12x20x2-1/2 deep pans, enabling a total pan capacity suited for large production runs. Operators can batch cook multiple trays per cycle to accelerate meal assembly and reduce holding time.

#@@# Powerful Electric Output#@#

Rated at 24,000 watts and 208 volts with a 3-phase configuration, the unit produces consistent steam generation for dense loads. Engineers will note that the 67 amp draw and 60 hertz specification match typical commercial electrical infrastructure.

#@@# Safety and Certification#@#

The unit meets cUL, UL, and NSF certifications and conforms to CSD-1 where applicable, providing documented compliance for institutional buyers. Facilities managers receive assurance that the design fulfills regulatory expectations for steam cooking equipment.

#@@#Delivery Details#@#

• Please ensure to handle the product with utmost care.

• Check if the product you have received has all the essential parts and accessories.

• Make sure to examine the product for damage before signing the delivery receipt.

• Contact customer service for delivery concerns.

• Delivery times may vary based on location.#@@#deliverynotes#@#NA#@@#Maintenance Guide#@#Inspect seals and hinges weekly to prevent steam loss and maintain temperature consistency. Descale water lines monthly using manufacturer-approved descaler to avoid scale buildup that reduces heat transfer. Flush condensate traps weekly and verify dual water connections for leaks. Lubricate door gaskets with silicone-based lubricant quarterly and replace damaged gaskets immediately. Calibrate manual controls semiannually and document maintenance actions to comply with CSA and NSF requirements.