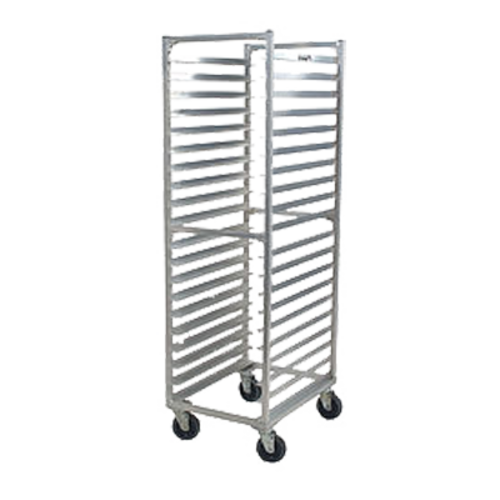

Stop compromising on storage efficiency and mobility. This heavy-duty pan rack combines optimized tray capacity with lightweight aluminum construction, providing kitchens with reliable transport and organized holding for high-volume service. Designed for end loading and frequent movement, this unit balances capacity, durability, and maneuverability for professional operations.

LongDescription#@#NA#@@#Cleaning Instructions#@#Wipe aluminum frame and trays with a mild detergent and warm water using a soft cloth; rinse and dry immediately to prevent spotting. Sanitize high-touch zones (handle edges, caster stems) with an EPA-registered sanitizer per label contact time. Inspect and tighten caster fasteners weekly. Remove food debris from shelf crevices to deter pests and prevent contamination of clean pans and hands. Regular cleaning preserves appearance and helps meet visible health-code expectations.#@@#Additional Info#@#Carter-Hoffmann O8619 20.5" W aluminum end-load pan rack holds 20 full-size 18" x 26" trays on 1.5" spacing, measures 20.5" W x 26.5" D x 39.44" H, rolls on 5" casters, features extruded side panels, CSA compliant, assembled and ready for service.#@@#General Info#@#Description #@#

Stop compromising on storage efficiency and mobility. This heavy-duty pan rack combines optimized tray capacity with lightweight aluminum construction, providing kitchens with reliable transport and organized holding for high-volume service. Designed for end loading and frequent movement, this unit balances capacity, durability, and maneuverability for professional operations.

#@@# Capacity Optimization#@#

This rack accepts 18 by 26 trays with 1.5-inch spacing and holds sixteen to twenty pans depending on tray thickness, enabling compact storage without stacking damage. Operators gain clear sight lines to trays and predictable spacing for consistent airflow and cooling during transport.

#@@# Aluminum Construction#@#

The unit uses aluminum components to reduce overall weight while resisting corrosion in humid or refrigerated spaces, yielding a long useful life in active kitchens. Staff members can move the rack with less effort compared to steel equivalents, lowering strain during frequent repositioning.

#@@# End Loading System#@#

End loading allows technicians to slide trays in and out from the short side, accelerating staging and reducing aisle congestion in tight kitchens. Line cooks and service staff can perform rapid load and unload cycles without rotating heavy racks.

#@@# Mobility Casters#@#

Five-inch casters provide smooth rolling over tile and sealed concrete while maintaining stability under full load, enabling controlled movement between prep, oven, and service areas. Maintenance crews can clean around wheels quickly and replace a caster with minimal downtime.

#@@# Open Style Design#@#

The open frame provides full access for cleaning and visual inventory checks, preventing hidden debris accumulation and simplifying sanitation workflows. Supervisors can verify tray counts at a glance and meet regulatory cleaning protocols with fewer disassembly steps.

#@@#Delivery Details#@#

• Please ensure to handle the product with utmost care.

• Check if the product you have received has all the essential parts and accessories.

• Make sure to examine the product for damage before signing the delivery receipt.

• Contact customer service for delivery concerns.

• Delivery times may vary based on location.#@@#deliverynotes#@#NA#@@#Maintenance Guide#@#Inspect casters weekly and tighten bolts to manufacturer specs; replace any caster with lateral play or noise. Clean aluminum surfaces with pH-neutral detergent and warm water, then rinse and dry to prevent residue and corrosion. Remove trays and flush channels with compressed air or a soft brush to clear crumbs. Lubricate caster bearings quarterly with food-grade lubricant. Verify the rack is square and level; adjust wheel locks before loading.