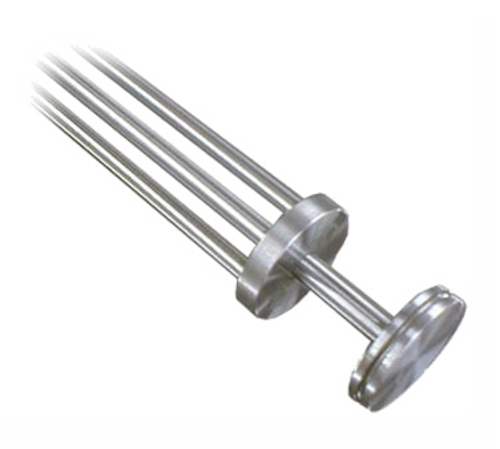

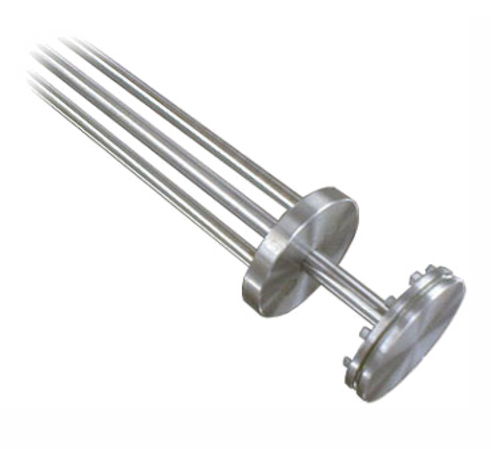

High-capacity production and precise portion control converge in a stainless steel plunger designed for continuous donut production lines. Tailored for industrial depositors, this plunger ensures consistent forming of 1-1/2 inches to 2 inches across production runs, minimizing scrap and maintaining uniform cook times. Operators will experience immediate throughput gains and tighter size distribution when they replace worn plungers with this durable steel component.

LongDescription#@#NA#@@#Cleaning Instructions#@#Unplug and cool the fryer before you work. Remove the Belshaw N-1009SS Donut Plunger and scrub with a soft brush and warm water mixed with mild detergent. Rinse thoroughly and sanitize per CSA or local rules. Inspect stainless surfaces for pitting; replace if damaged. Dry completely to prevent corrosion. Clean surrounding vents and oil traps to stop grease buildup and reduce fire risk, energy draw, and equipment wear. Reinstall only when dry.#@@#Additional Info#@#Belshaw N-1009SS Donut Plunger fits type N depositors and operates with 1-1/2" to 2" plungers, stainless steel construction, 1 pound weight, and requires matching cylinder sizes for proper function; contact manufacturer for sizing code and pricing.#@@#General Info#@#Description #@#

High-capacity production and precise portion control converge in a stainless steel plunger designed for continuous donut production lines. Tailored for industrial depositors, this plunger ensures consistent forming of 1-1/2 inches to 2 inches across production runs, minimizing scrap and maintaining uniform cook times. Operators will experience immediate throughput gains and tighter size distribution when they replace worn plungers with this durable steel component.

#@@# Material Integrity#@#

Stainless steel construction resists corrosion and withstands repeated mechanical stress in hot, humid frying environments. Technicians will find that the metal surface maintains dimensional stability over extended service intervals, preserving portion accuracy and reducing maintenance frequency.

#@@# Size Compatibility#@#

This plunger fits type N depositors that accept plungers sized between 1-1/2 inches and 2 inches, providing flexibility across common ring dies. Production managers can select the appropriate plunger to match die openings, ensuring each unit forms the intended donut profile without requiring operator adjustments.

#@@# Operational Consistency#@#

Engineered tolerances maintain punch concentricity and stroke repeatability under high-cycle operation, which preserves weight control and frying time uniformity. Kitchen supervisors will limit product variance and achieve predictable yield metrics across shifts.

#@@# Serviceability#@#

The design allows for straightforward removal and replacement by maintenance staff, minimizing downtime during changeovers or cleaning cycles. Facilities can complete routine swaps without specialized tools, keeping lines operational during peak periods.

#@@# Sanitation Performance#@#

Smooth stainless surfaces simplify cleaning and resist residue adhesion, supporting HACCP routines and reducing the risk of microbial harborage. Sanitation crews will complete washdowns more quickly, lowering labor time allocated to parts cleaning.

#@@#Delivery Details#@#

• Please ensure to handle the product with utmost care.

• Check if the product you have received has all the essential parts and accessories.

• Make sure to examine the product for damage before signing the delivery receipt.

• Contact customer service for delivery concerns.

• Delivery times may vary based on location.#@@#deliverynotes#@#NA#@@#Maintenance Guide#@#Inspect the Belshaw N-1009SS donut plunger weekly to ensure the plunger diameter and cylinder match for consistent deposit size. Remove residues after each shift by soaking the stainless steel component in warm, soapy water, then scrub with a nylon brush; sanitize with an approved food-grade sanitizer and rinse as directed. Lubricate moving seals with a food-grade lubricant monthly and check for wear; replace seals or damaged plungers immediately to prevent contamination.