The heavy-duty 2-compartment airpot serving rack organizes dual airpots for continuous service while protecting floors and staff from spills. It combines robust capacity with streamlined handling for busy service lines.

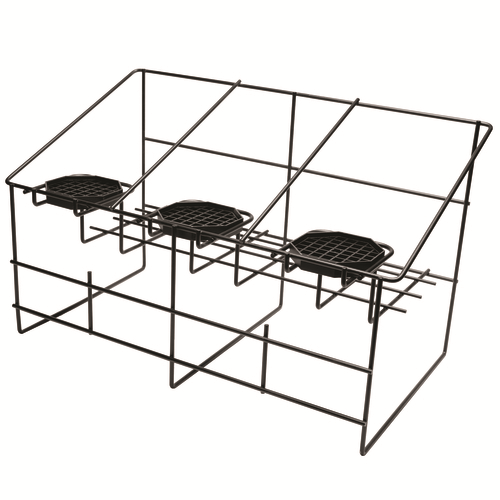

LongDescription#@#NA#@@#Cleaning Instructions#@#Wipe rack daily with a mild detergent solution and a soft cloth, removing airpot drips from the removable drip trays. Rinse and air dry; hand wash only. Sanitize high-touch zones (tray edges, interlock points, handles) with an EPA-registered surface sanitizer to prevent Norovirus and cold-virus transfer between staff and customers. Clean under shelves and around serving stations to deter pests and maintain health-code compliance. Regular care preserves finish and service life.#@@#Additional Info#@#Service Ideas APR2BLC 20" black stainless steel rack organizes two airpots in a 20" x 13" space and stands 9" high; removable drip trays allow easy cleaning, powder-coated wire resists corrosion, and interlock links support double or triple setups.#@@#General Info#@#Description #@#

The heavy-duty 2-compartment airpot serving rack organizes dual airpots for continuous service while protecting floors and staff from spills. It combines robust capacity with streamlined handling for busy service lines.

The rack measures 20 inches wide by 13 inches deep by 9 inches high, designed to accommodate two standard airpots side by side. Designers optimized the footprint to mount on counters and carts where space is limited while keeping access to lids and pumps unobstructed.

The powder-coated stainless steel wire resists chipping and maintains a consistent appearance under repeated cleaning cycles. Staff will rely on the finish to limit corrosion and preserve structural integrity in high-humidity environments.

Two compartments secure airpots separately to prevent tipping and cross-contamination during service. Operators will find filling and swapping containers faster and safer with defined placement for each unit.

Black removable drip trays collect overflow and simplify cleanup after peak periods. Crew members can easily remove trays, empty them, and return the rack to service without tools, reducing downtime between uses.

The interlock design supports double and triple configurations for scalable deployment across lines and stations. Managers can expand capacity by linking racks to match fluctuating service demands.

Designers specified hand wash maintenance to preserve the coating and fasteners, enabling routine sanitation without risking damage from aggressive machine cycles. Maintenance teams will perform quick cleaning that keeps the unit compliant with food service hygiene practices.

#@@#Delivery Details#@#

• Please ensure to handle the product with utmost care.

• Check if the product you have received has all the essential parts and accessories.

• Make sure to examine the product for damage before signing the delivery receipt.

• Contact customer service for delivery concerns.

• Delivery times may vary based on location.#@@#deliverynotes#@#NA#@@#Maintenance Guide#@#Inspect powder-coated stainless steel wire daily for corrosion spots and remove debris from removable black drip trays after each service to prevent buildup. Clean unit by hand wash using a neutral pH detergent and warm water; rinse thoroughly and air dry to maintain finish. Verify interlock mechanisms engage smoothly and adjust alignment if trays bind. Tighten fasteners monthly and replace worn components per CSA guidelines to sustain safe, reliable operation.