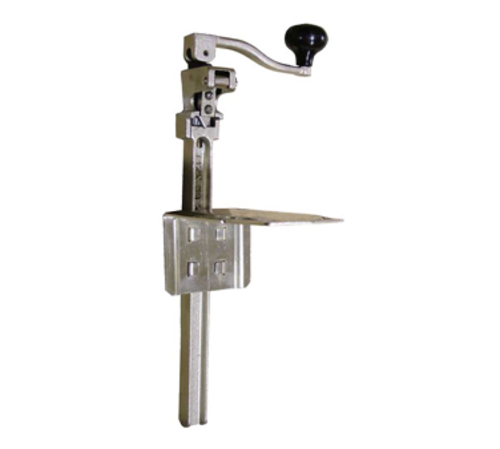

Stop sacrificing durability for ease of use. This cast iron, screw-down can opener delivers consistent, heavy-duty performance for high-volume kitchens while remaining simple to operate and maintain. Designed for table mounting, it handles cans up to 7 inches and mounts securely to worktables, keeping operations steady during peak service.

LongDescription#@#NA#@@#Cleaning Instructions#@#Unplug nearby equipment and clear the area. Clamp the base securely. Remove the blade assembly and wash with warm, soapy water; scrub residue with a non-abrasive brush. Sanitize food-contact parts per CSA or local guidelines using approved sanitizer at labeled dilution. Dry all components and lubricate the shaft with food-grade lubricant. Reassemble, test on an empty can up to 7" diameter, and tighten the mount. Clean daily to prevent bacteria, grease fires, higher bills, and equipment failure.#@@#Additional Info#@#Omcan USA's Edlund #2 cast iron can opener mounts to a worktable and cuts cans up to 7". It has a screw-down base for stability, weighs 7 pounds, and suits high-volume foodservice settings needing durable, CSA-compliant tools.#@@#General Info#@#Description #@#

Stop sacrificing durability for ease of use. This cast iron, screw-down can opener delivers consistent, heavy-duty performance for high-volume kitchens while remaining simple to operate and maintain. Designed for table mounting, it handles cans up to 7 inches and mounts securely to worktables, keeping operations steady during peak service.

#@@# Mounting Security#@#

Installers secure the unit to counters using the screw-down base, providing firm anchoring during repetitive use. Technicians will appreciate the straightforward attachment that minimizes wobble and supports one-handed can manipulation, enhancing efficiency.

#@@# Robust Construction#@#

Manufacturers crafted the body from cast iron to withstand constant daily use in commercial settings. Operators will notice that the dense construction reduces flex and resists deformation under heavy loads, significantly extending service life and reliability.

#@@# Precision Cutting#@#

Engineers equipped the opener with a #2 cutting head designed for consistent penetration and smooth lid removal. Staff will achieve predictable results with fewer jagged lids, improving safety and reducing product loss, which is crucial in busy kitchens.

#@@# Capacity Range#@#

Design specifications support cans up to 7 inches, accommodating common foodservice container sizes without requiring multiple devices. Managers will streamline back-of-house workflow by using a single unit for soups, sauces, and bulk ingredients, enhancing productivity.

#@@# Maintenance Access#@#

Technicians can perform routine blade and gear servicing without disassembling the entire assembly, thanks to accessible fasteners and replaceable components. Maintenance teams will reduce downtime and keep the unit in service with minimal spare parts on hand, ensuring operational continuity.

#@@#Delivery Details#@#

• Please ensure to handle the product with utmost care.

• Check if the product you have received has all the essential parts and accessories.

• Make sure to examine the product for damage before signing the delivery receipt.

• Contact customer service for delivery concerns.

• Delivery times may vary based on location.#@@#deliverynotes#@#NA#@@#Maintenance Guide#@#Inspect the screw-down mount daily and tighten bolts to prevent movement. Lubricate the rotating shaft and cutting wheel monthly with a food-grade lubricant to maintain smooth operation. Replace the cutting wheel when nicks or burrs appear to reduce can deformation. Clean cast iron surfaces after each shift using a mild detergent and dry thoroughly to prevent rust; apply a thin oil film for corrosion protection. Verify alignment before each use to ensure safe cutting.