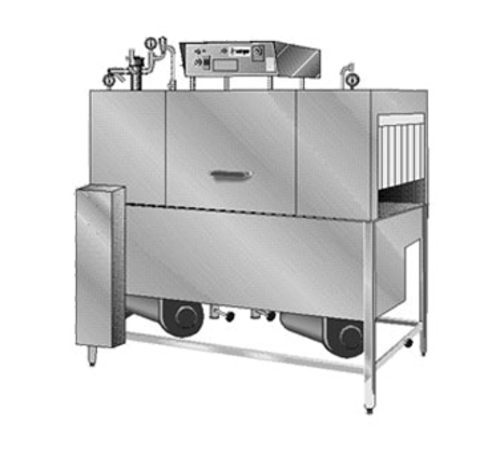

Handle peak service with a machine engineered for continuous throughput and consistent thermal sanitization. This conveyor dishwasher processes approximately 277 racks per hour using a two-tank wash and rinse layout, along with a CrossFire® wash system to maintain cleaning performance without a booster. Food service managers will gain a predictable production rate and stainless steel durability designed for busy kitchens.

LongDescription#@#NA#@@#Cleaning Instructions#@#Unplug and lock out power before work. Remove racks and debris. Scrub tunnels and spray arms with a food-safe detergent; rinse with potable water. Descale heating elements and tanks monthly using approved descaler at manufacturer concentration; flush until clear. Clean conveyor tracks and exterior with nonabrasive cleaner; dry all surfaces. Inspect door seals, spray nozzles, and drains; replace worn parts. Record cleaning, water temps, and chemical concentrations for CSA audits.#@@#Additional Info#@#The Insinger SPEEDER (64") conveyor dishwasher delivers 277 racks per hour with a two-tank, high-temp CrossFire® wash system; stainless steel, NSF certification, and U.S. manufacture ensure efficient sanitization and durability.#@@#General Info#@#Description #@#

Handle peak service with a machine engineered for continuous throughput and consistent thermal sanitization. This conveyor dishwasher processes approximately 277 racks per hour using a two-tank wash and rinse layout, along with a CrossFire® wash system to maintain cleaning performance without a booster. Food service managers will gain a predictable production rate and stainless steel durability designed for busy kitchens.

#@@# Stainless Construction#@#

The stainless steel frame, legs, and feet deliver structural resilience and corrosion resistance under heavy use. Operators benefit from a hygienic exterior that withstands daily cleaning protocols and supports a long service life.

#@@# High Temperature Wash#@#

High temperature operation without a booster provides thermal sanitization that meets many institutional health standards. Facilities receive reliable sanitizing rinse temperature while avoiding added booster complexity.

#@@# Two Tank Design#@#

The two-tank configuration separates wash and rinse functions to optimize chemical dosing and rinse effectiveness. Managers achieve consistent soil removal and controlled rinse chemistry for repeatable results.

#@@# CrossFire Wash System#@#

CrossFire® delivers targeted water flow patterns to improve soil removal on stacked ware and utensils. Staff experience fewer rewash cycles and reduced manual pre-scrubbing time.

#@@# Capacity Throughput#@#

Rated for approximately 277 racks per hour, this conveyor supports high-volume cafeterias, hospitals, and hotels during peak periods. Supervisors can plan labor and service times around a measurable processing rate.

#@@# Electric Tank Heat#@#

Electric immersion tank heat provides stable wash temperature control and simplifies utility hookups where steam may not suit the installation. Maintenance teams gain straightforward electrical components and predictable heating performance.

#@@#Delivery Details#@#

• Please ensure to handle the product with utmost care.

• Check if the product you have received has all the essential parts and accessories.

• Make sure to examine the product for damage before signing the delivery receipt.

• Contact customer service for delivery concerns.

• Delivery times may vary based on location.#@@#deliverynotes#@#NA#@@#Maintenance Guide#@#Inspect the Insinger SPEEDER (64") conveyor dishwasher daily for soil, scale, and wear. Clean wash and rinse filters; soak in a mild alkaline solution, rinse, and reinstall. Flush the wash tank weekly and descale with an approved acid sanitizer per CSA guidelines; use personal protective equipment. Check spray nozzles and CrossFire® manifolds for patterns and replace clogged tips. Monthly, check conveyor chain tension and guide alignment; lubricate pivot points with food-grade lubricant.