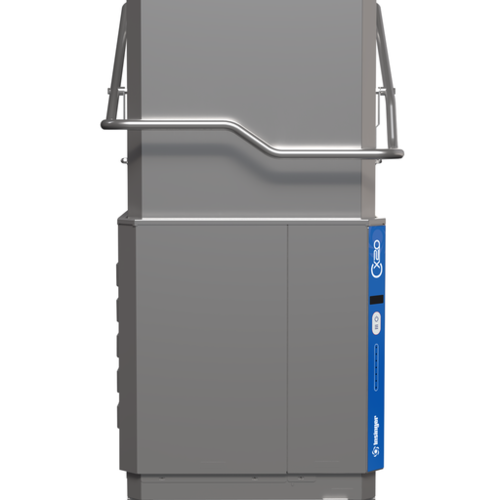

Stop sacrificing throughput for sanitation. This flight-type dishwasher delivers continuous high-temperature cleaning capacity while integrating robust construction for long duty cycles, making it ideal for high-volume food service environments. Designed for facilities that require consistent, repeatable cleaning performance, the unit supports heavy loads with automated controls and a CrossFire wash system.

LongDescription#@#NA#@@#Cleaning Instructions#@#Unplug and lock out the CENTURY (+21') before service. Remove visible debris from conveyor and wash chambers. Flush tanks and drain; refill with fresh water and sanitizer per CSA guidelines. Scrub spray nozzles, conveyor belts, and gaskets using a mild detergent and soft brush. Descale heating elements and clean condenser coils to maintain efficiency. Inspect seals and replace worn parts. Dry all surfaces completely before restoring power to prevent corrosion and electrical faults.#@@#Additional Info#@#Insinger’s CENTURY (+21') 252" stainless steel flight dishwasher runs at 208 volts, 3-phase, 60 Hz. It features a 26" conveyor, processes 14,300 dishes/hour, and weighs 3,750 pounds.#@@#General Info#@#Description #@#

Stop sacrificing throughput for sanitation. This flight-type dishwasher delivers continuous high-temperature cleaning capacity while integrating robust construction for long duty cycles, making it ideal for high-volume food service environments. Designed for facilities that require consistent, repeatable cleaning performance, the unit supports heavy loads with automated controls and a CrossFire wash system.

#@@# Tank Capacity#@#

The dishwasher processes approximately 124 gallons per hour, enabling sustained cleaning during peak service periods. Operators maintain consistent temperature and chemical levels through automatic tank fill, which reduces manual intervention.

#@@# Conveyor Width#@#

A conveyor width of 26 inches accommodates large trays and varied load types to maximize yield per pass. Technicians can adjust throughput by controlling conveyor speed to match kitchen workflow.

#@@# High Temperature Operation#@#

The system operates at high-temperature specifications to meet sanitization targets and supports NSF certification for commercial compliance. Engineers can select electric immersion or steam injector tank heat depending on plant utilities and recovery requirements.

#@@# Structural Construction#@#

The stainless steel frame, legs, and feet provide structural rigidity and resist corrosion in humid dishroom environments. Maintenance crews can access removable panels and standard components to streamline routine service.

#@@# Electrical Configuration#@#

The machine requires 208 volts, 3-phase, 60 Hertz power to deliver rated performance and integrate with commercial electrical systems. Facility planners must verify service capacity and breaker sizing before installation.

#@@# Throughput and Size#@#

The flight spans approximately 21 feet in length and measures 252 inches in width for large-scale operations, supporting roughly 14,300 dish capacity per hour under rated conditions.

#@@#Delivery Details#@#

• Please ensure to handle the product with utmost care.

• Check if the product you have received has all the essential parts and accessories.

• Make sure to examine the product for damage before signing the delivery receipt.

• Contact customer service for delivery concerns.

• Delivery times may vary based on location.#@@#deliverynotes#@#NA#@@#Maintenance Guide#@#Inspect wash arms and nozzles weekly; clear blockages with a soft brush. Verify chemical feed lines and pumps monthly; replace cracked tubing and calibrate dosing. Flush the tank weekly and remove scale with approved cleaners; rinse thoroughly. Confirm conveyor alignment and chain tension biweekly; adjust rollers and replace worn sprockets. Test thermostat and high-limit controls monthly; log readings. Check door seals and fasteners during inspections; tighten or replace as needed.