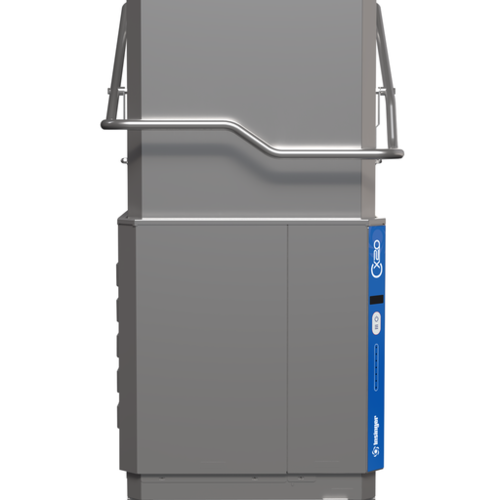

Stop sacrificing throughput for sanitation. This flight-type dishwasher delivers continuous high-temperature wash cycles and industrial capacity, allowing operations to move faster while meeting strict sanitation standards. Facility managers gain reproducible results and measurable cleaning rates during peak service periods.

LongDescription#@#NA#@@#Cleaning Instructions#@#Unplug the conveyor and lock out power. Remove racks and scrape solids. Flush spray nozzles and run a mild detergent through the CrossFire wash system. Brush tank and conveyor belts with non-abrasive pads; vacuum or wipe condenser coils. Rinse with hot water and check that the automatic tank fill works. Inspect door seals and stainless steel surfaces; polish with appropriate cleaner. Record cleaning frequency to prevent grease buildup, equipment failure, and failed CSA inspections.#@@#Additional Info#@#Insinger's CENTURY (18') 216" stainless steel flight dishwasher runs at 208v, 3-Ph, 60 Hz, offering high-temp CrossFire wash with a 26" conveyor, 18' length, 8,736-dish hourly capacity, automatic tank fill, and CSA certified, made in USA.#@@#General Info#@#Description #@#

Stop sacrificing throughput for sanitation. This flight-type dishwasher delivers continuous high-temperature wash cycles and industrial capacity, allowing operations to move faster while meeting strict sanitation standards. Facility managers gain reproducible results and measurable cleaning rates during peak service periods.

#@@# Wide Conveyor#@#

A 216-inch conveyor accommodates large racks and varied dish sizes, enabling a steady flow through the system. Operators can stage items without bottlenecks, preserving line rhythm and reducing manual handling time.

#@@# High Temperature#@#

The system operates at high temperatures to achieve required sanitization levels and complies with NSF Certified protocols. Maintenance teams experience reduced chemical dependency because thermal sanitization effectively handles bioburden.

#@@# CrossFire Wash#@#

The CrossFire wash system concentrates spray patterns for improved soil removal on stacked items and utensils. Supervisors note consistent wash quality across a full load, lowering rewash rates and labor costs.

#@@# High Capacity#@#

The conveyor design achieves approximately 8,736 dishes per hour and processes 124 gallons per hour, delivering predictable throughput for large institutions. Planners can align staffing and service windows to real output rather than estimates.

#@@# Robust Construction#@#

The stainless steel frame, legs, and feet provide corrosion resistance and structural stability for continuous operation in demanding kitchens. Engineers appreciate long runtimes between structural inspections and minimal panel warping under heat.

#@@# Flexible Heat Options#@#

Engineers can select electric immersion or steam injector tank heat to match site utilities and thermal recovery needs; factory consultation clarifies pricing and configuration. Procurement teams gain installation flexibility for 208v, 3-Ph power systems that meet existing electrical infrastructure.

#@@#Delivery Details#@#

• Please ensure to handle the product with utmost care.

• Check if the product you have received has all the essential parts and accessories.

• Make sure to examine the product for damage before signing the delivery receipt.

• Contact customer service for delivery concerns.

• Delivery times may vary based on location.#@@#deliverynotes#@#NA#@@#Maintenance Guide#@#Inspect conveyor belts daily for wear and adjust tension per manufacturer specifications to maintain consistent throughput. Drain and flush wash and rinse tanks weekly; replace filters and inspect pumps for debris. Descale heating elements monthly when water hardness exceeds recommended levels. Lubricate bearings and chain links with food-grade lubricant on a scheduled basis. Verify thermostat calibration and test overflow alarms quarterly to ensure operational safety.