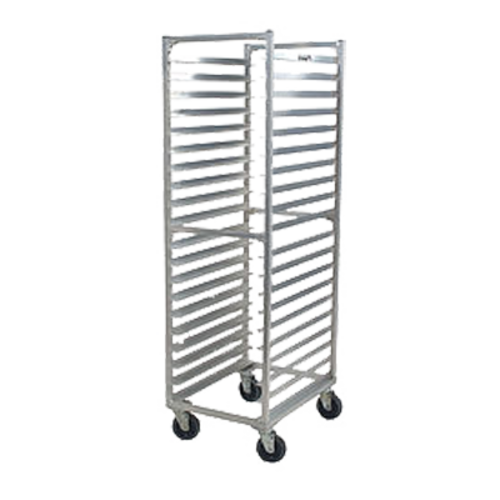

Stop compromising floor space for capacity. This aluminum end load pan rack delivers organized transport and high pan density for production kitchens, holding up to 36 full-size trays while maintaining a compact footprint and easy access for loading and unloading operations. Designed for continuous use in institutional and commercial settings, this rack balances strength, mobility, and corrosion resistance to support heavy daily cycles.

LongDescription#@#NA#@@#Cleaning Instructions#@#Wipe aluminum rack and slides with a mild detergent solution and a soft cloth; rinse and dry thoroughly. Sanitize high-touch zones like handles, caster stems, and tray guides with an approved sanitizer at label concentration. Inspect casters and frame weekly; tighten fasteners and remove food debris under shelves. Regular cleaning prevents contamination of clean items and hands, supports health-code compliance, deters pests, and preserves rack finish.#@@#Additional Info#@#Carter-Hoffmann O8636 40.13" W aluminum end-load pan rack holds 36 18" x 26" trays on fixed-angle slides with 3" spacing, measures 40.13" W x 26.25" D x 64.19" H, offers open sides, double-width construction, 5" casters, and weighs 159 pounds.#@@#General Info#@#Description #@#

Stop compromising floor space for capacity. This aluminum end load pan rack delivers organized transport and high pan density for production kitchens, holding up to 36 full-size trays while maintaining a compact footprint and easy access for loading and unloading operations. Designed for continuous use in institutional and commercial settings, this rack balances strength, mobility, and corrosion resistance to support heavy daily cycles.

#@@# Capacity Optimization#@#

This rack accepts 36 to 40 full-size pans in a double-width configuration, enabling kitchens to stage large batches without expanding staging areas. Users gain predictable spacing at 3 inches between slides to ensure even airflow and consistent product handling during cooling or proofing cycles.

#@@# Aluminum Durability#@#

Constructed from aluminum, the unit resists corrosion and reduces overall weight compared with steel alternatives, simplifying repositioning during service and cleaning. Operators will notice reduced strain when maneuvering the rack while preserving structural integrity under repeated loading.

#@@# End Loading Access#@#

The end load design permits fast insertion and removal of pans from the short end, speeding turnover on busy lines and minimizing aisle obstruction. Staff can stage trays quickly during peak windows, reducing task time for both preparation and cleanup.

#@@# Fixed Angle Slides#@#

Fixed angle slides provide stable support for each tray while maintaining alignment and preventing sag under full loads, which protects fragile finished products and contributes to consistent handling. Maintenance teams will appreciate the low complexity of fixed slides that require minimal adjustment.

#@@# Mobility Package#@#

Five-inch casters allow smooth movement across typical kitchen floors and facilitate transport between prep, baking, and storage areas without elevated effort. Facilities gain reliable maneuverability for redistribution of large batches during service transitions.

#@@#Delivery Details#@#

• Please ensure to handle the product with utmost care.

• Check if the product you have received has all the essential parts and accessories.

• Make sure to examine the product for damage before signing the delivery receipt.

• Contact customer service for delivery concerns.

• Delivery times may vary based on location.#@@#deliverynotes#@#NA#@@#Maintenance Guide#@#Inspect caster mounting and wheel bearings weekly; tighten fasteners and replace worn wheels to preserve mobility. Clean aluminum surfaces with a pH-neutral detergent and soft brush, rinse thoroughly, and dry to prevent staining. Lubricate slide channels with food-grade lubricant every month, removing debris first. Verify end-loading stops and welds quarterly; repair cracks immediately. Balance loads to prevent rack twist and check tray spacing for uniform airflow.