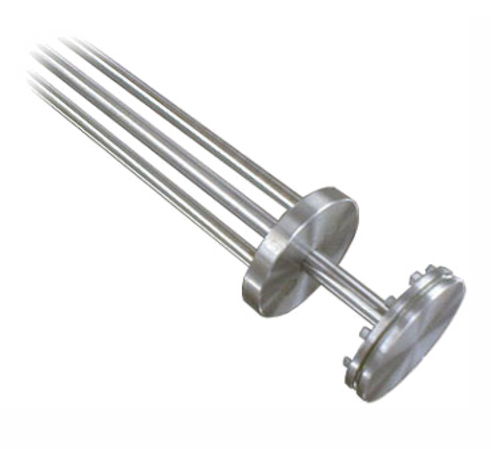

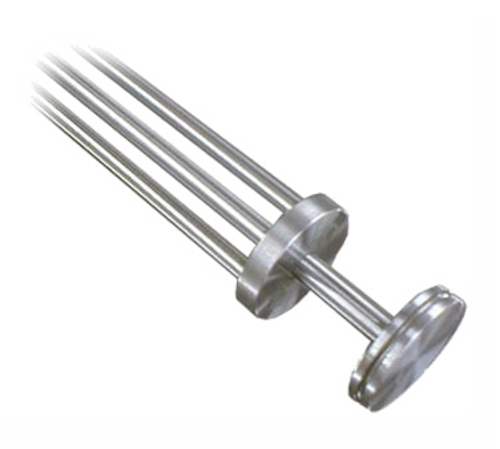

Increase throughput without sacrificing portion consistency with a heavy-duty loukoumades plunger designed for continuous production. This stainless component fits type N depositors and ejects uniform 2-inch rounds through three 3/4-inch orifices for precise dough drop control. Food service teams gain predictable yields, faster line speed, and reduced downtime with a durable design built for repetitive cycles.

LongDescription#@#NA#@@#Cleaning Instructions#@#Unplug equipment and let parts cool before cleaning. Remove the Belshaw N-1009BSS-103C plunger and soak in warm, soapy water for 10 minutes. Scrub holes with a soft brush to dislodge batter; rinse with potable water. Sanitize per CSA guidelines using approved solution, then air dry on a clean rack. Clean fryer and vents to remove grease so you reduce fire risk, lower energy use, prevent breakdowns, and pass inspections.#@@#Additional Info#@#Belshaw N-1009BSS-103C Loukoumades plunger fits type N depositors. It has a 2" body with three 3/4" holes for consistent batter portioning, made of durable stainless steel, weighing 1 pound, and is compatible with commercial donut fryers.#@@#General Info#@#Description #@#

Increase throughput without sacrificing portion consistency with a heavy-duty loukoumades plunger designed for continuous production. This stainless component fits type N depositors and ejects uniform 2-inch rounds through three 3/4-inch orifices for precise dough drop control. Food service teams gain predictable yields, faster line speed, and reduced downtime with a durable design built for repetitive cycles.

#@@# Durability and Fit#@#

Engineers constructed the plunger from corrosion-resistant materials to withstand hot oil environments and frequent cleaning. Technicians install the unit on type N depositors using the provided mounting pattern, ensuring secure alignment and minimal play for consistent operation.

#@@# Consistent Portion Control#@#

Precision-placed 3/4-inch round holes deliver uniform loukoumades size and weight every cycle. Operators maintain product quality and reduce waste because each shot produces similar dough volume and shape.

#@@# Cycle Reliability#@#

Thick section design resists deformation under repeated plunging, preserving hole geometry and delivery characteristics. Production teams avoid variances that cause rejects or uneven frying times.

#@@# Serviceability Features#@#

A straightforward geometry simplifies access for inspection and routine maintenance without special tools. Maintenance staff complete cleaning and replacement tasks quickly, minimizing production interruptions.

#@@# Weight and Handling#@#

At approximately one pound, the component balances robustness with manageable handling during installation or service. Line personnel manipulate the plunger safely and align it without assistance, supporting quick changeover.

#@@# Compatibility and Inventory#@#

Manufacturing tolerances match type N depositor interfaces to maintain interchangeability across matching equipment fleets. Procurement managers streamline spare parts inventory because the plunger integrates with standard depositor platforms.

#@@#Delivery Details#@#

• Please ensure to handle the product with utmost care.

• Check if the product you have received has all the essential parts and accessories.

• Make sure to examine the product for damage before signing the delivery receipt.

• Contact customer service for delivery concerns.

• Delivery times may vary based on location.#@@#deliverynotes#@#NA#@@#Maintenance Guide#@#Inspect the Belshaw N-1009BSS-103C Loukoumades plunger before each shift for wear, deformation, or clogged 3/4" holes. Disassemble and soak components in warm, soapy water; scrub with a nylon brush and rinse thoroughly. Sanitize per facility protocol, then air-dry before reassembly. Lubricate movable seals with food-grade lubricant monthly. Store in a clean, dry area away from corrosive chemicals to ensure consistent deposit accuracy and extend service life.