Manufactured for commercial frying systems, the attachment endures repetitive cycles typical in institutional and retail kitchens. Procurement teams receive a component that sustains performance under rigorous daily use while aligning with existing fryer system workflows.

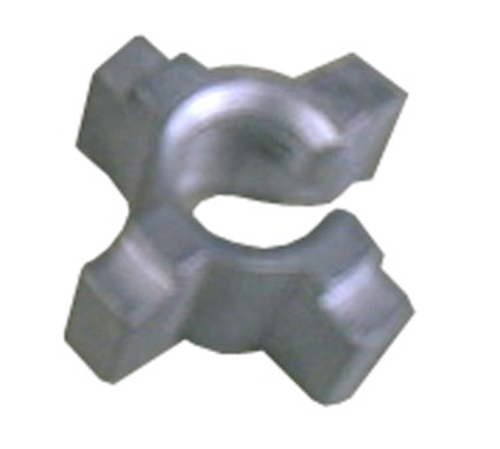

LongDescription#@#NA#@@#Cleaning Instructions#@#Unplug the Donut Robot or Type K before servicing. Remove the DR42-1018X1.563 Dunkerette attachment and soak in warm water with a mild detergent. Scrub all crevices with a soft-bristled brush to remove oil and batter. Rinse with hot water and air dry or towel dry thoroughly. Inspect mounting points and replace worn seals. Clean surrounding fryer areas to remove grease buildup to reduce fire risk, lower energy use, and prevent contamination.#@@#Additional Info#@#Belshaw’s DR42-1018X1.563 Dunkerette Attachment fits Donut Robot® and Type K machines, mounts to K-1011A or K-1011S, and cuts two half donuts per cycle, enhancing production consistency for fry lines.#@@#General Info#@#Description #@#

Manufactured for commercial frying systems, the attachment endures repetitive cycles typical in institutional and retail kitchens. Procurement teams receive a component that sustains performance under rigorous daily use while aligning with existing fryer system workflows.#@@#Delivery Details#@#

• Please ensure to handle the product with utmost care.

• Check if the product you have received has all the essential parts and accessories.

• Make sure to examine the product for damage before signing the delivery receipt.

• Contact customer service for delivery concerns.

• Delivery times may vary based on location.#@@#deliverynotes#@#NA#@@#Maintenance Guide#@#Inspect the Belshaw DR42-1018X1.563 Dunkerette Attachment before each shift and verify secure mounting to K-1011A or K-1011S frameworks. Disassemble per CSA guidelines and soak components in warm, soapy solution; use nylon brushes to remove dough buildup without abrading surfaces. Rinse thoroughly and air dry; reassemble only when fully dry. Lubricate moving joints with food-grade lubricant monthly and stock spare cutters to minimize downtime.