Built to streamline sanitation and drainage in busy kitchens, this stainless steel floor trough delivers exceptional performance for food service operations requiring durable, code-compliant plumbing solutions. Crafted from 14 gauge 304 stainless steel, the unit resists corrosion under continuous wet conditions and maintains structural integrity during heavy use. Facilities managers and kitchen operators will appreciate the combination of code adherence and serviceable design that reduces maintenance time and minimizes workflow interruptions.

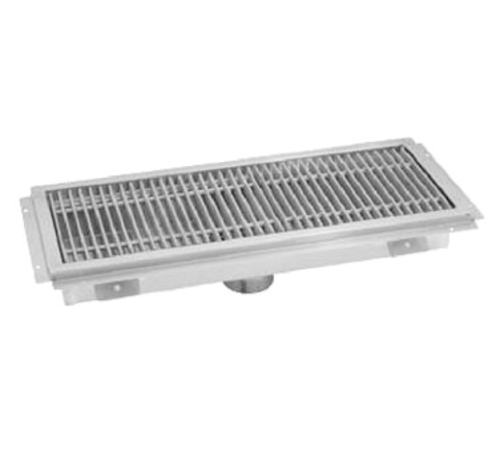

LongDescription#@#NA#@@#Cleaning Instructions#@#Unplug nearby equipment and clear the area. Remove grates and wash with warm, soapy water; rinse and dry. Scrub the trough interior with a mild detergent and a non-abrasive pad to remove grease and debris. Inspect welds, seals, and the 14 Gauge 304 stainless steel surface for damage; repair or replace worn parts. Flush the drain with hot water and an approved degreaser. Reinstall stainless steel grates and verify proper drainage before returning equipment to service.#@@#Additional Info#@#Advance Tabco FTG-1854 floor trough measures 54" W x 18" D x 4" H, made of 14 Gauge 304 stainless steel with grates. It weighs 122 pounds, meets NSF certification, and offers durable, corrosion-resistant drainage for foodservice and plumbing.#@@#General Info#@#Description #@#

Built to streamline sanitation and drainage in busy kitchens, this stainless steel floor trough delivers exceptional performance for food service operations requiring durable, code-compliant plumbing solutions. Crafted from 14 gauge 304 stainless steel, the unit resists corrosion under continuous wet conditions and maintains structural integrity during heavy use. Facilities managers and kitchen operators will appreciate the combination of code adherence and serviceable design that reduces maintenance time and minimizes workflow interruptions.

#@@# Durable 14 Gauge Body#@#

Constructed from 14 gauge 304 stainless steel, the trough offers a rigid profile that withstands foot traffic and equipment loading. Operators will benefit from a long service life and predictable wear characteristics, which reduce replacement frequency and lifecycle costs.

#@@# Code Compliant Design#@#

Engineers specified NSF certification to ensure compliance with health and safety codes for commercial installations. Plumbing teams will find that this approval simplifies inspections and reduces project delays during commissioning.

#@@# Optimized Width And Depth#@#

Measuring 54 inches wide and 18 inches deep, the trough accommodates linear drainage requirements across long prep lines or dish areas. Maintenance staff will benefit from ample capacity that prevents frequent overflow and reduces spill response time.

#@@# Low-Profile Installation#@#

Standing at 4 inches high, the low-profile trough integrates seamlessly with floor layouts where minimal vertical intrusion is essential. Facility planners can maintain accessible walkways while delivering effective drainage without raised tripping hazards.

#@@# Robust Grate Construction#@#

Equipped with stainless steel grates, the unit provides reliable solids handling and resists deformation from carts and pushes. Cleaning crews will find straightforward grate removal for routine washdown and clog prevention.

#@@#Delivery Details#@#

• Please ensure to handle the product with utmost care.

• Check if the product you have received has all the essential parts and accessories.

• Make sure to examine the product for damage before signing the delivery receipt.

• Contact customer service for delivery concerns.

• Delivery times may vary based on location.#@@#deliverynotes#@#NA#@@#Maintenance Guide#@#Inspect stainless steel surfaces daily and remove debris from grates to prevent clogging and corrosion. Use pH-neutral detergent and warm water for cleaning; rinse and dry with a microfiber cloth to avoid water spots. Schedule a weekly deep clean: lift grates, flush trough with hot water, apply food-safe sanitizer, scrub corners with a nylon brush, then reassemble. Verify drain connections and seals monthly and torque fasteners to specs. Record maintenance actions for CSA audits.