Handle high-volume can storage efficiently without wasting floor space or staff time. This aluminum mobile rack provides organized, gravity-fed storage for #10 and #5 cans while delivering a durable, corrosion-resistant platform for busy back-of-house operations. Designed for continuous use, this unit supports rapid stock rotation and simplifies inventory access during peak service periods.

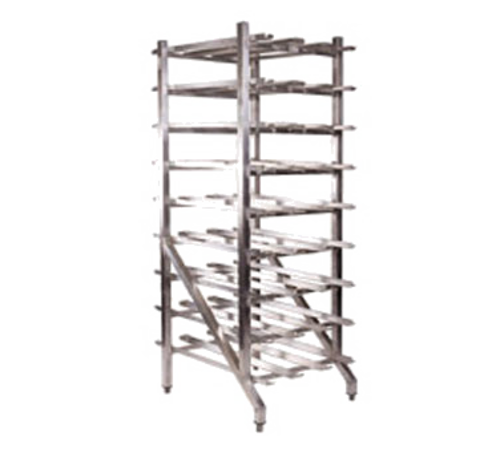

LongDescription#@#NA#@@#Cleaning Instructions#@#Wipe aluminum surfaces with mild detergent and warm water; rinse and dry to prevent corrosion. Sanitize high-touch areas like handles and top with EPA-registered sanitizer per label; allow contact time. Vacuum debris from shelves and under rack; remove spills immediately to deter pests and stop staining. Inspect casters and welds weekly; tighten hardware as needed. Regular cleaning prevents cross-contamination, supports health-code compliance, and maintains appearance and service life.#@@#Additional Info#@#Winholt's CR-72M mobile aluminum can rack measures 27.5" W by 40" H with a 35" depth, features welded aluminum frame and top, self-feeding gravity shelves that store up to 72 #10 or 96 #5 cans, NSF certified and weighs 58 pounds.#@@#General Info#@#Description #@#

Handle high-volume can storage efficiently without wasting floor space or staff time. This aluminum mobile rack provides organized, gravity-fed storage for #10 and #5 cans while delivering a durable, corrosion-resistant platform for busy back-of-house operations. Designed for continuous use, this unit supports rapid stock rotation and simplifies inventory access during peak service periods.

#@@# Capacity Optimization#@#

This rack holds up to 72 #10 cans or 96 #5 cans, enabling consolidated storage that reduces trips to dry storage. Managers gain predictable stocking density and tighter inventory control, which lowers retrieval time and labor costs.

#@@# Gravity Feed Shelves#@#

Gravity-fed shelves automatically move cans forward, ensuring first-in, first-out rotation and a steady supply at the worktop. Staff access products from the front without manual reshuffling, speeding up prep and reducing handling errors.

#@@# Mobile Footprint#@#

Four swivel casters provide full mobility, allowing staff to reposition the rack for staging, cleaning, or receiving. Operators maneuver the unit with minimal effort, improving workflow flexibility in confined kitchen or storeroom spaces.

#@@# Robust Aluminum Construction#@#

The welded aluminum frame and top deliver corrosion resistance and a lightweight profile that resists warping under frequent use. Supervisors can easily maintain sanitary conditions because aluminum resists moisture and cleans with standard detergents.

#@@# Low-Profile Work Top#@#

The integrated worktop creates a staging surface for portioning and labeling while keeping the unit compact at 27.5 inches wide. Line cooks and prep staff use the top for immediate tasks, reducing the need to move cans to separate countertops.

#@@# Regulatory Compliance#@#

NSF certification confirms the rack meets public health standards for commercial food storage, supporting compliance during inspections.

#@@#Delivery Details#@#

• Please ensure to handle the product with utmost care.

• Check if the product you have received has all the essential parts and accessories.

• Make sure to examine the product for damage before signing the delivery receipt.

• Contact customer service for delivery concerns.

• Delivery times may vary based on location.#@@#deliverynotes#@#NA#@@#Maintenance Guide#@#Inspect wheels and caster mounts weekly; tighten fasteners to ensure mobility and prevent failure. Clean the aluminum frame and top with a pH-neutral cleaner and soft cloth to remove grease and salts; avoid chlorides that cause corrosion. Cycle shelves under load to confirm the gravity-feed mechanism moves freely; remove debris from roller channels and apply a light food-grade lubricant to hinges. Verify NSF label visibility and document inspections in a maintenance log.