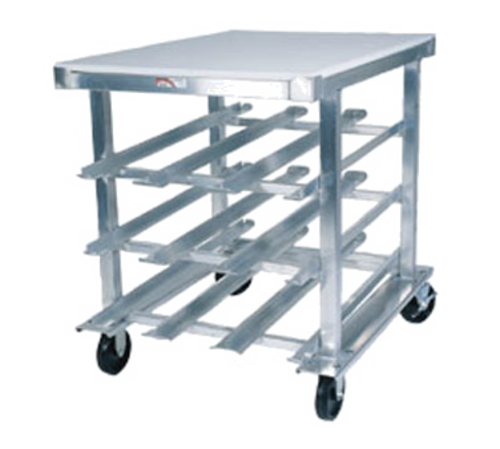

Stop wasting storage space on inefficient shelving solutions when a purpose-built mobile can rack delivers organized, fast access, and reliable durability. This all-aluminum mobile can rack optimizes back-of-house workflow for kitchens that process high volumes of canned goods, supporting continuous restocking and inventory rotation with gravity-fed shelves and a compact footprint.

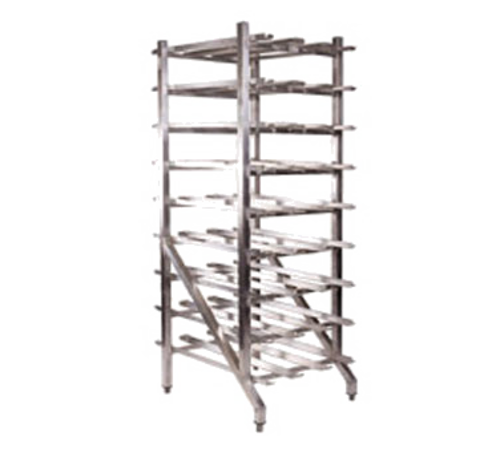

LongDescription#@#NA#@@#Cleaning Instructions#@#Clean aluminum rack daily to prevent contamination of clean items and hands. Wipe shelves, chair-back-height rails, and casters with a detergent solution, then disinfect high-touch zones using EPA-registered sanitizer per label directions. Remove loose food and debris from crevices to deter pests. Rinse, dry, and inspect welds and fasteners; tighten as needed. Routine cleaning preserves appearance, helps pass health inspections, and supports a safer customer experience.#@@#Additional Info#@#Winholt CR-162M mobile can rack measures 27 1/2" W x 35" D x 76" H. It has a 65-pound NSF-certified frame made of 1 1/2" welded aluminum tubing. Casters allow transport, and gravity-fed shelves store up to 162 #10 or 216 #5 cans.#@@#General Info#@#Description #@#

Stop wasting storage space on inefficient shelving solutions when a purpose-built mobile can rack delivers organized, fast access, and reliable durability. This all-aluminum mobile can rack optimizes back-of-house workflow for kitchens that process high volumes of canned goods, supporting continuous restocking and inventory rotation with gravity-fed shelves and a compact footprint.

#@@# Mobile Design#@#

This unit mounts on heavy-duty casters for effortless repositioning across service and storage areas. Staff can move the rack without tools, reducing setup time and improving ergonomics during restock cycles.

#@@# Gravity Fed Shelves#@#

Self-feeding angled shelves push cans forward automatically, ensuring first-in, first-out rotation and minimizing manual handling. Operators maintain consistent supply at the front of the rack, reducing pick time during peak periods.

#@@# High Capacity#@#

The rack accommodates up to 162 #10 cans or 216 #5 cans, providing large volume storage within a 27.5-inch wide by 35-inch deep footprint. Managers consolidate inventory and free floor space while keeping stock visible and accessible.

#@@# Aluminum Frame#@#

Fabricated from 1.5-inch welded aluminum tubing, the structure resists corrosion and supports repeated daily use in humid kitchen environments. Maintenance crews clean and sanitize the frame quickly, preserving hygiene standards.

#@@# NSF Certified#@#

The design meets NSF criteria for back-of-house storage equipment, supporting compliance with food safety audits. Facilities can rely on documented certification during inspections and procurement reviews.

#@@# Compact Height#@#

At 76 inches tall, the rack offers substantial vertical storage without exceeding typical ceiling constraints in commercial kitchens. Purchasing teams can maximize storage density while maintaining clearance for overhead fixtures.

#@@#Delivery Details#@#

• Please ensure to handle the product with utmost care.

• Check if the product you have received has all the essential parts and accessories.

• Make sure to examine the product for damage before signing the delivery receipt.

• Contact customer service for delivery concerns.

• Delivery times may vary based on location.#@@#deliverynotes#@#NA#@@#Maintenance Guide#@#Inspect the Winholt CR-162M rack weekly and tighten caster fasteners to maintain safe mobility. Clean aluminum tubing with a mild detergent solution and a nonabrasive cloth to prevent corrosion and preserve finish. Verify gravity-fed shelves operate freely; remove obstructions and lubricate hinges with food‑grade lubricant quarterly. Measure rack loads to avoid exceeding rated capacity and balance cans evenly across shelves to prevent tipping. Keep NSF documentation on file.