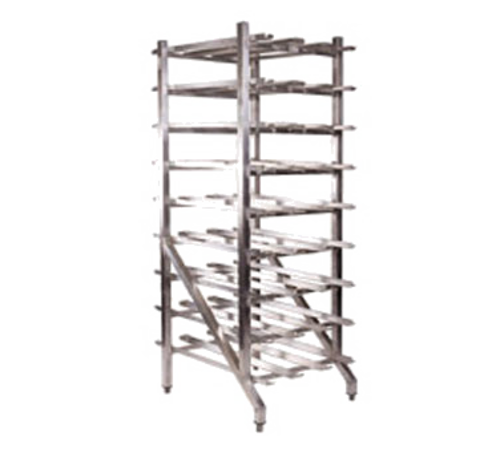

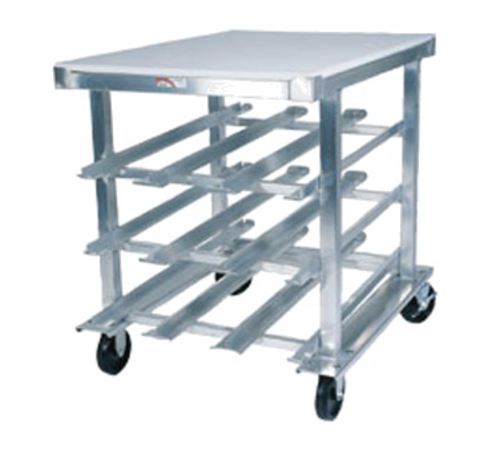

This can storage rack organizes high-volume kitchens and storerooms while delivering steady supply flow for constant pick rates. Designed for industrial use, the unit maximizes vertical space and supports fast restocking and inventory rotation without mechanical components.

LongDescription#@#NA#@@#Cleaning Instructions#@#Wipe rack surfaces daily with a mild detergent and hot water, scrub shelf grooves where food debris collects, then rinse and dry to prevent corrosion. Sanitize high-touch zones like handles and edges with an EPA-registered sanitizer according to label contact time. Inspect welds and shelf alignment weekly; tighten or replace hardware if needed. Clean prevents cross-contamination between front- and back-of-house, deters pests, preserves finish, and helps pass health inspections.#@@#Additional Info#@#Winholt CR-162 stores 162 #10 cans or 216 #5 cans on gravity-fed aluminum shelves for FIFO rotation and quick access.#@@#General Info#@#Description #@#

This can storage rack organizes high-volume kitchens and storerooms while delivering steady supply flow for constant pick rates. Designed for industrial use, the unit maximizes vertical space and supports fast restocking and inventory rotation without mechanical components.

The frame resists corrosion and stands up to daily handling in humid environments. Installers will value the lightweight structure that simplifies placement while delivering durable support for loaded shelves.

Shelves feed cans forward automatically, enabling first-in, first-out rotation and reducing manual sorting time. Managers will notice faster service lines and fewer expired stock incidents because workers access the oldest stock first.

The rack stores a flexible number of cans, offering density options depending on can size and inventory needs. Planners can configure storage layout to match menu demands and back of house volume without additional shelving.

Measuring 25.25 inches wide by 35 inches deep and 71 inches high, the unit maximizes vertical capacity while minimizing floor usage in tight kitchens. Operators who need to free floor space for prep stations will find the tall profile especially useful.

Certification verifies the rack meets public health and sanitation standards for commercial kitchens, supporting compliance during inspections. Maintenance teams will appreciate surfaces that clean easily and reduce contamination risk.

The stationary design ensures stable, vibration-free storage for stacked cans and minimizes accidental movement in busy environments. Facilities staff will set the rack once, then rely on consistent positioning for inventory control and kitchen flow.

#@@#Delivery Details#@#

• Please ensure to handle the product with utmost care.

• Check if the product you have received has all the essential parts and accessories.

• Make sure to examine the product for damage before signing the delivery receipt.

• Contact customer service for delivery concerns.

• Delivery times may vary based on location.#@@#deliverynotes#@#NA#@@#Maintenance Guide#@#Inspect welds and frame weekly for deformation or corrosion, and tighten bolts to maintain integrity. Vacuum tracks and shelf channels monthly to remove debris that impedes gravity feed. Sanitize contact surfaces with a food-grade cleaner after heavy use, then rinse and air dry to prevent residue. Lubricate moving pins with a food-safe lubricant semiannually for consistent shelf movement. Verify load distribution and do not exceed rated can capacity.