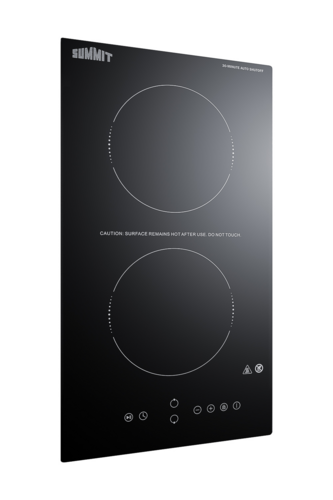

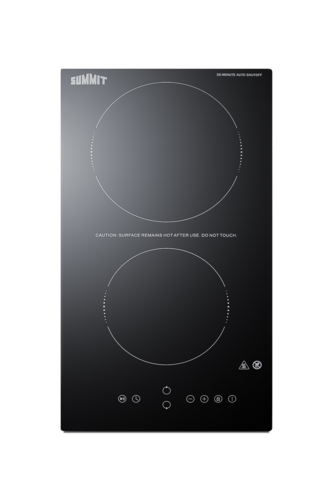

Compact countertop cooking power engineered for continuous service, this two-zone electric radiant cooktop delivers precise heat control and reliable performance for cafeterias, bars, and satellite kitchens. Designed for built-in installations where footprint and electrical compatibility matter, the unit pairs a smooth ceramic glass surface with digital controls to simplify operations and reduce cleaning time. Operators who need consistent heat, low maintenance, and clear power ratings will find this cooktop integrates with existing 115/120v circuits without complex wiring changes.

LongDescription#@#NA#@@#Cleaning Instructions#@#Unplug the cooktop and let surfaces cool. Remove loose debris with a soft brush. Mix warm water with mild detergent (use gallons or liters as needed) and wipe the ceramic glass top with a non-abrasive cloth. Clean control knobs and crevices with a soft toothbrush. Rinse with clean water and dry thoroughly. Inspect vents and underside; vacuum coils to prevent heat buildup and fires. Perform daily wipe downs and weekly deep cleans to maintain safety and efficiency.#@@#Additional Info#@#Summit CRH2BT30115 is an 11.88" wide, 2-burner ceramic glass cooktop rated 115/120v and 1200 Watts, with digital controls, ETL certification, and a compact 11.38" width for countertops; it has a 20.5" depth and weighs 10 pounds.#@@#General Info#@#Description #@#

Compact countertop cooking power engineered for continuous service, this two-zone electric radiant cooktop delivers precise heat control and reliable performance for cafeterias, bars, and satellite kitchens. Designed for built-in installations where footprint and electrical compatibility matter, the unit pairs a smooth ceramic glass surface with digital controls to simplify operations and reduce cleaning time. Operators who need consistent heat, low maintenance, and clear power ratings will find this cooktop integrates with existing 115/120v circuits without complex wiring changes.

#@@# Ceramic Glass Surface#@#

Ceramic glass provides an even, flat working area that supports pans with consistent contact, reducing hotspot formation for uniform cooking outcomes. Staff can clean the surface quickly after service since spills wipe away without abrasive tools, preserving both appearance and sanitation.

#@@# Dual Heating Zones#@#

Two independently controlled burners offer simultaneous preparation of multiple items during rush periods, maximizing throughput on a narrow 11.88-inch footprint. Kitchen teams can adjust each zone to match pan size and recipe requirements, enabling parallel production without cross-interference.

#@@# Digital Control Interface#@#

Digital controls allow operators to set and maintain precise temperatures, improving repeatability across shifts and reducing product waste from overheating. Technicians can calibrate settings quickly and verify performance through straightforward readouts, simplifying staff training.

#@@# 115/120v Compatibility#@#

Design supports common 115/120v supply standards used in many commercial prep stations, eliminating the need for specialized voltage conversions in most installations. Facilities can integrate the unit into existing electrical layouts with minimal modifications, lowering installation time and cost.

#@@#Delivery Details#@#

• Please ensure to handle the product with utmost care.

• Check if the product you have received has all the essential parts and accessories.

• Make sure to examine the product for damage before signing the delivery receipt.

• Contact customer service for delivery concerns.

• Delivery times may vary based on location.#@@#deliverynotes#@#Please provide a complete address and contact number for delivery. Inspect the packaging to ensure the product is in good condition.#@@#Maintenance Guide#@#Inspect the cooktop surface daily and remove food debris with a nonabrasive cloth and pH-neutral cleaner; avoid steel wool and acidic detergents that damage the ceramic glass. Calibrate digital controls monthly by following the manufacturer manual and verify voltage at 115/120v to prevent electrical stress. Clean spill sensors and vent openings with compressed air. Replace damaged gaskets or controls immediately. Document maintenance intervals and CSA or ETL labels during inspections.