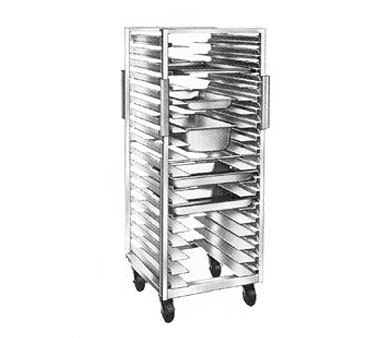

Dependable transport and storage for high-volume kitchens reduces handling time and protects inventory while maximizing floor space and throughput. This aluminum tray rack features a mobile, wide-opening design that accommodates common pan sizes with minimal effort, allowing staff to load and move large quantities with consistent alignment and stability. Operations benefit from predictable performance thanks to a welded extruded aluminum frame and robust casters designed for demanding food service environments.

LongDescription#@#NA#@@#Cleaning Instructions#@#Clean tray rack surfaces after each shift. Use mild detergent and warm water; scrub slides and openings with a nylon brush to remove grease. Rinse with clean water and dry with a lint-free cloth. Sanitize high-touch zones—handles, side rails, caster stems—with an EPA-registered sanitizer per label directions. Inspect for residue under shelves to prevent pests and maintain compliance. Regular cleaning preserves appearance and reduces cross-contamination.#@@#Additional Info#@#Piper Products UW66-18 Tray Rack offers mobile, full-height storage for 12" x 20" to 18" x 26" pans. It features a welded aluminum frame, end-load access, 5" casters, fixed slides, 18-pair capacity, and weighs 175 pounds.#@@#General Info#@#Description #@#

Dependable transport and storage for high-volume kitchens reduces handling time and protects inventory while maximizing floor space and throughput. This aluminum tray rack features a mobile, wide-opening design that accommodates common pan sizes with minimal effort, allowing staff to load and move large quantities with consistent alignment and stability. Operations benefit from predictable performance thanks to a welded extruded aluminum frame and robust casters designed for demanding food service environments.

#@@# Universal Slides#@#

Slides accept 12 inches x 20 inches through 18 inches x 26 inches pans on approximately 3-inch centers, enabling flexible use across multiple pan formats. Managers achieve efficient staging and retrieval because the rack supports diverse production schedules without the need for adapter plates.

#@@# Full Height Construction#@#

The full height configuration provides complete vertical support across the rack, reducing pan sag and maintaining consistent clearances for stacked products. Supervisors benefit from easier inventory counts and safer transport since pans remain secure during movement.

#@@# End Load Access#@#

End loading simplifies the placement and removal of pans in tight kitchen layouts, cutting transfer time at production lines and ovens. Chefs maintain workflow continuity due to the straightforward, single-side access that aligns with common pass and prep setups.

#@@# Fixed Slide Capacity#@#

Fixed slides provide an 18-pair capacity, delivering predictable spacing and consistent airflow around pans during cooling or staging. Engineers appreciate the reduced maintenance requirements compared to adjustable systems, lowering downtime for service.

#@@# Welded Aluminum Frame#@#

Welded extruded aluminum construction yields strength with reduced weight, resisting corrosion in humid kitchen conditions while remaining easy to maneuver. Facility staff experience a longer service life and consistent dimensional stability under frequent use.

#@@#Delivery Details#@#

• Please ensure to handle the product with utmost care.

• Check if the product you have received has all the essential parts and accessories.

• Make sure to examine the product for damage before signing the delivery receipt.

• Contact customer service for delivery concerns.

• Delivery times may vary based on location.#@@#deliverynotes#@#NA#@@#Maintenance Guide#@#Inspect casters weekly and tighten hardware to maintain mobility and prevent floor damage. Clean the aluminum frame and slides with nonabrasive detergent and warm water; rinse and dry to avoid oxidation. Verify slide alignment and clear debris from channels every 3 inches to ensure pans seat correctly. Lubricate swivel caster bearings quarterly with light machine oil. Check welds and end-load fittings for cracks; repair before use.