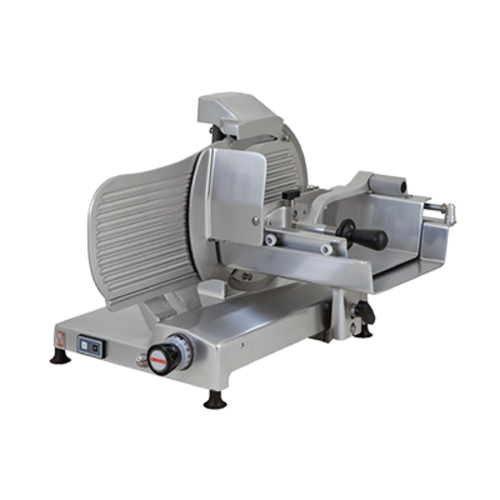

Stop compromising throughput for precision. This electric kebab slicer efficiently handles heavy daily loads while ensuring consistent slice thickness and operator safety, providing kitchens with predictable output and reduced labor time. Designed for high-volume gyro and shawarma service, the unit delivers controlled cuts with simple adjustments and robust components suited for continuous use.

LongDescription#@#NA#@@#Cleaning Instructions#@#Unplug unit before cleaning. Remove blade guard and wipe stainless blade holder and orifice plate with a mild soap solution and soft cloth. Rinse parts, dry completely, and reassemble. Clean plastic fiber nylon body with non-abrasive cleaner. Inspect seals and overload protection area for debris. Clean vents and exterior regularly to prevent grease build-up that raises fire risk, increases energy use, and can cause equipment failure.#@@#Additional Info#@#Omcan USA’s electric kebab slicer 40280 processes 132.3 pounds daily with an 80 Watt motor at 110 volts, 60 Hz, 1-Ph.#@@#General Info#@#Description #@#

Stop compromising throughput for precision. This electric kebab slicer efficiently handles heavy daily loads while ensuring consistent slice thickness and operator safety, providing kitchens with predictable output and reduced labor time. Designed for high-volume gyro and shawarma service, the unit delivers controlled cuts with simple adjustments and robust components suited for continuous use.

#@@# Capacity Control#@#

This slicer processes a workload equivalent to 132.3 gallons, translating to a daily cutting capacity of 132.3 pounds, supporting sustained peak production in cafeterias and catering lines. Operators achieve predictable throughput rates that align with service windows and staffing levels.

#@@# Adjustable Thickness#@#

Technicians can set the cutting depth up to 1/3 inch and quickly adjust thickness to suit various meat profiles and menu specifications. Chefs maintain portion uniformity for consistent cook times and plating, effectively reducing rework and waste.

#@@# Durable Cutting System#@#

The blade mounts in a stainless steel holder and seats against a stainless orifice plate, delivering corrosion resistance where food contact is critical. Maintenance crews can access a blade protector for safe cleaning and replacement without exposing sharp edges.

#@@# Motor Efficiency#@#

An 80-watt motor drives the slicing action on a 110-volt, 60 Hz, single-phase supply, providing sufficient torque for continuous operation while limiting electrical draw. Engineers benefit from predictable power consumption and straightforward integration into existing electrical circuits.

#@@# Operator Safety#@#

The design includes overload protection and a blade protector that prevents accidental contact during operation and service. Supervisors can reduce injury risk and comply with standard safety expectations without sacrificing accessibility for routine tasks.

#@@#Delivery Details#@#

• Please ensure to handle the product with utmost care.

• Check if the product you have received has all the essential parts and accessories.

• Make sure to examine the product for damage before signing the delivery receipt.

• Contact customer service for delivery concerns.

• Delivery times may vary based on location.#@@#deliverynotes#@#NA#@@#Maintenance Guide#@#Inspect blade edge daily and tighten blade holder bolts to maintain slicing accuracy. Lubricate motor bearings monthly with food-grade lubricant following CSA guidelines to ensure reliable operation. Clean orifice plate and blade guard after each shift using mild detergent and warm water; rinse and dry thoroughly to prevent corrosion. Verify overload protection functions quarterly by testing under controlled load. Record maintenance actions and replace worn parts promptly to minimize downtime.