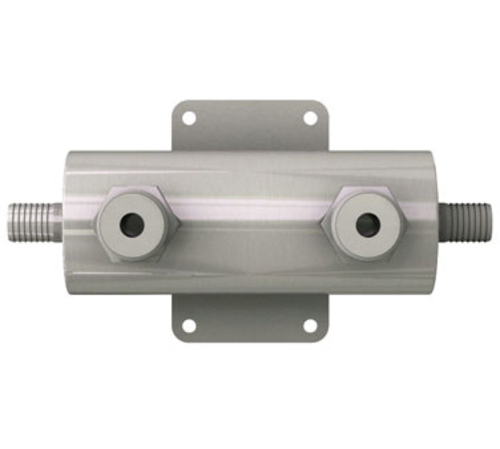

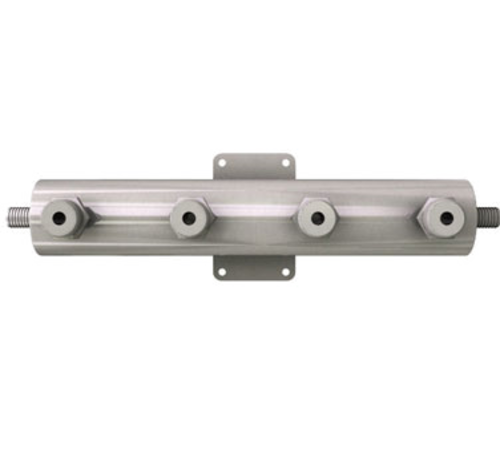

Handle high-volume draft lines without compromise, delivering precise flow control across two dispensing points while maintaining consistent performance under continuous use. Designed for bar, restaurant, and institutional draft systems, this two-station manifold accepts a 0.5-inch barb inlet and routes product with minimal pressure loss. Installers will appreciate the compact footprint and straightforward plumbing interface that speeds setup and reduces labor time.

LongDescription#@#NA#@@#Cleaning Instructions#@#Unplug draft lines and relieve keg pressure. Disconnect manifold and inspect for debris. Flush with warm water, then circulate a 1:4 bleach solution for sanitation; rinse thoroughly until no bleach odor remains. Remove buildup from barb inlets with a soft brush. Air-dry completely before reassembly. Clean weekly for frequent use; document each service to meet CSA and health inspections. Regular cleaning prevents contamination, fires, efficiency loss, and equipment failure.#@@#Additional Info#@#Micro Matic 2837 0.5" barb inlet beer manifold offers precise flow control for draft systems, mounts with standard fittings, resists corrosion, and allows dispensing from two lines; CSA-compliant materials ensure reliability.#@@#General Info#@#Description #@#

Handle high-volume draft lines without compromise, delivering precise flow control across two dispensing points while maintaining consistent performance under continuous use. Designed for bar, restaurant, and institutional draft systems, this two-station manifold accepts a 0.5-inch barb inlet and routes product with minimal pressure loss. Installers will appreciate the compact footprint and straightforward plumbing interface that speeds setup and reduces labor time.

#@@# Inlet Compatibility#@#

Accepts a 0.5-inch barb inlet that integrates with standard tubing sizes used in commercial draft systems. Technicians will connect lines rapidly and achieve secure seals that reduce leak potential and downtime.

#@@# Dual Output Design#@#

Provides two independent stations that distribute product from a single supply source, enabling simultaneous service to multiple taps. Operators will maintain uniform pressure between lines when configured properly, supporting consistent pour quality during peak periods.

#@@# Flow Efficiency#@#

Engineers optimized internal passages to minimize turbulence and pressure drop across the unit, which preserves carbonation and flavor profiles. Staff will notice steady pours and fewer adjustments to regulator settings during service.

#@@# Durable Construction#@#

Constructed from materials suited for repeated contact with carbonated products and cleaning solutions, the assembly resists corrosion and mechanical wear. Maintenance teams will perform routine cleaning with confidence and extend component life cycles.

#@@# Serviceability#@#

Features an accessible layout that allows routine inspection and quick replacement of tubing or fittings without dismantling adjacent equipment. Service intervals shrink and total labor for upkeep falls, improving operational uptime.

#@@#Delivery Details#@#

• Please ensure to handle the product with utmost care.

• Check if the product you have received has all the essential parts and accessories.

• Make sure to examine the product for damage before signing the delivery receipt.

• Contact customer service for delivery concerns.

• Delivery times may vary based on location.#@@#deliverynotes#@#NA#@@#Maintenance Guide#@#Inspect manifold connections weekly for signs of leakage, corrosion, or wear and tighten fittings to 10–12 ft·lb torque where specified. Flush beer lines monthly with approved cleaner at recommended concentration and volume to maintain flavor integrity; circulate for at least 20 minutes then rinse with potable water until residual cleaner tests neutral. Sanitize manifolds before peak service and replace o-rings annually. Verify pressure stability and check gauges after maintenance.