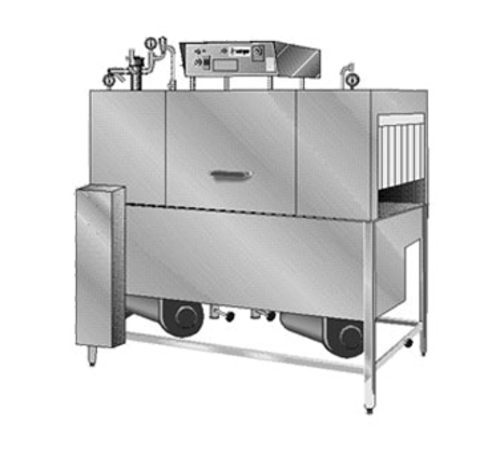

When throughput determines profit, you need equipment that ensures continuous service without compromise. This high-temperature flight conveyor system processes around 14,300 dishes per hour, supporting rapid turnarounds in high-volume operations while delivering consistent sanitization and reducing labor bottlenecks. Operators benefit from a robust stainless steel frame and engineered controls that streamline wash cycles while adhering to commercial sanitation standards.

LongDescription#@#NA#@@#Cleaning Instructions#@#Unplug power and lock out energy. Remove debris from conveyor and spray with 140°F wash solution. Scrub wash and rinse manifolds, tanks, and spray arms with non-abrasive detergent. Flush drains and clean filters daily. Degrease vents and hood weekly to reduce fire risk. Wash exterior stainless surfaces with mild cleaner and dry. Inspect seals, conveyor belts, and heating elements; replace worn parts. Regular cleaning prevents contamination, fires, higher bills, and equipment failure.#@@#Additional Info#@#Insinger’s CENTURY 17 flight dishwasher offers high-temperature cleaning with a 17' conveyor, 26" wash tunnel, CrossFire® wash system, automatic tank fill, and options for electric or steam heat.#@@#General Info#@#Description #@#

When throughput determines profit, you need equipment that ensures continuous service without compromise. This high-temperature flight conveyor system processes around 14,300 dishes per hour, supporting rapid turnarounds in high-volume operations while delivering consistent sanitization and reducing labor bottlenecks. Operators benefit from a robust stainless steel frame and engineered controls that streamline wash cycles while adhering to commercial sanitation standards.

#@@# Conveyor Capacity#@#

This conveyor runs approximately 17 feet long and measures about 26 inches wide, enabling continuous processing of large dish loads to match peak service periods. Facilities achieve predictable flow rates and maintain steady output at 306 gallons per hour water usage, simplifying utility planning and scheduling.

#@@# High Temperature Sanitation#@#

The system operates as a high-temperature dishwasher with electric immersion or steam injector tank heat options, producing thermal sanitation that meets regulatory requirements and ensures effective pathogen reduction. Managers retain control over heat source selection to align with facility utilities and maintenance preferences.

#@@# Wash Technology#@#

The CrossFire® wash system delivers targeted spray action across the conveyor path, maximizing cleaning performance while minimizing rewash incidents. Supervisors observe reduced manual intervention and sustained cleanliness across various serviceware types.

#@@# Construction Durability#@#

Engineers designed the unit with a full stainless steel frame, legs, and feet to resist corrosion in aggressive commercial environments and support continuous duty cycles. Maintenance teams benefit from accessible components and a design that facilitates scheduled servicing without extensive downtime.

#@@# Water Management#@#

Automatic tank fill controls maintain consistent water levels and reduce operator tasks associated with manual replenishment, stabilizing wash chemistry and cycle reliability.

#@@#Delivery Details#@#

• Please ensure to handle the product with utmost care.

• Check if the product you have received has all the essential parts and accessories.

• Make sure to examine the product for damage before signing the delivery receipt.

• Contact customer service for delivery concerns.

• Delivery times may vary based on location.#@@#deliverynotes#@#NA#@@#Maintenance Guide#@#Inspect conveyor belts daily for wear and alignment to prevent jams and uneven washing. Calibrate thermostat and verify high temperature sanitization cycles at least weekly. Drain and descale the tank monthly; flush automatic tank fill valves and strainers after heavy use. Clean CrossFire® nozzles and replace worn spray arms quarterly. Lubricate bearings and check leg fasteners on a scheduled basis to ensure consistent throughput and compliance with CSA standards.