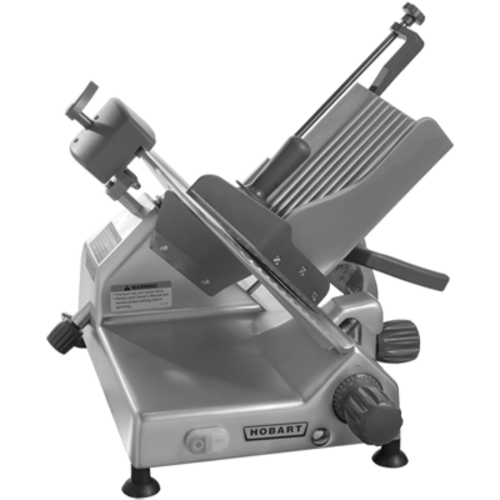

Power through high-volume slicing tasks with a durable, precision-engineered manual slicer that features a 12" aluminum knife and a centerline design, delivering consistent, uniform cuts ideal for busy kitchens. Designed for food service professionals, this unit operates on 120v and provides 1/2 HP of belt-driven power, maintaining blade speed under load for fast throughput without sacrificing slice quality. Built with stainless steel and aluminum, this slicer resists corrosion and simplifies daily cleaning, ensuring continuous, reliable operation.

LongDescription#@#NA#@@#Cleaning Instructions#@#Unplug the slicer and lock the blade guard. Remove carriage and wipe food contact surfaces with a mild detergent solution; rinse with clear water and dry with a lint-free cloth. Clean knife edge by hand per manufacturer instructions using a sanitizing solution approved by CSA standards. Degrease motor housing and drive belt area with a non-corrosive cleaner; inspect for wear. Reassemble, run a brief test cut, and record maintenance to reduce bacteria, fire risk, and breakdowns.#@@#Additional Info#@#Hobart EDGE12-11 manual slicer features a 12" aluminum knife, stainless steel construction, 1/2 HP belt drive at 120 volts, angle/gravity manual feed, meets CSA and CETLus certifications, and weighs 85 pounds.#@@#General Info#@#Description #@#

Power through high-volume slicing tasks with a durable, precision-engineered manual slicer that features a 12" aluminum knife and a centerline design, delivering consistent, uniform cuts ideal for busy kitchens. Designed for food service professionals, this unit operates on 120v and provides 1/2 HP of belt-driven power, maintaining blade speed under load for fast throughput without sacrificing slice quality. Built with stainless steel and aluminum, this slicer resists corrosion and simplifies daily cleaning, ensuring continuous, reliable operation.

12 Inch Knife

The 12" knife produces long, continuous slices, effectively handling whole hams, large roasts, and blocks of cheese with minimal repositioning. Operators achieve uniform thickness across large product volumes, enhancing portion control and reducing waste.

1/2 Horsepower Motor

The 1/2 HP motor supplies steady torque for consistent cutting performance during continuous use. Chefs maintain throughput without frequent slowdowns, while the belt drive absorbs shock, prolonging component life.

Manual Feed System

The manual feed allows operators to control slice speed and pressure for varied product textures. Experienced staff can adjust their feed technique to optimize yield and maintain precise slice profiles.

Centerline Configuration

The centerline layout positions the carriage for balanced, ergonomic operation, reducing operator fatigue. Teams can sustain production during extended shifts while maintaining cut accuracy.

Stainless Steel Construction

Stainless steel surfaces provide a corrosion-resistant exterior that withstands daily washdown and contact with food acids. Managers can lower downtime for repairs and preserve sanitary conditions with durable materials.

Belt Drive Design

The belt drive transfers motor energy smoothly to the knife, minimizing vibration and noise during high-volume runs.

#@@#Delivery Details#@#

• Please ensure to handle the product with utmost care.

• Check if the product you have received has all the essential parts and accessories.

• Make sure to examine the product for damage before signing the delivery receipt.

• Contact customer service for delivery concerns.

• Delivery times may vary based on location.#@@#deliverynotes#@#Upon confirmation of completed payment, Culinary Depot will ship/deliver the Hobart EDGE12-11 Meat Slicer.#@@#Maintenance Guide#@#Clean the knife and carriage daily with a mild detergent and warm water; remove residue to prevent corrosion. Inspect blade alignment and sharpen per manufacturer intervals using a certified stone; verify 12" knife edge for straightness. Lubricate slide rods and bearings weekly with food-grade lubricant. Tighten belt and check 1/2 HP drive tension monthly. Test safety interlocks and CSA markings before each shift to ensure compliant operation.