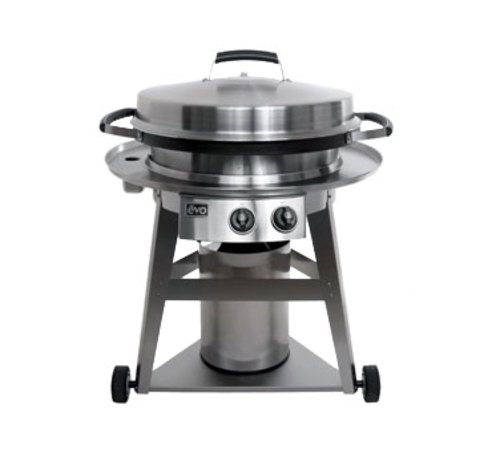

Built to enhance outdoor operations with controlled, repeatable results, this commercial freestanding cooking station features a 30" seasoned steel plancha with precise thermostatic control, ideal for high-volume grilling tasks. Food service teams benefit from a spacious usable surface and dual-zone temperature control, allowing for searing, griddling, and gentle finishing without the need for equipment swaps. Operators will appreciate the electronic ignition, integrated tools, and NSF certification, which simplify service and compliance.

LongDescription#@#NA#@@#Cleaning Instructions#@#Unplug and close propane supply before cleaning. Scrape excess food with the included stainless steel scraper. Use warm water and a mild detergent; apply with a soft cloth and wipe in circular motions across the 30" seasoned steel surface. Rinse with clean water and dry immediately to prevent rust. Clean burner areas and open shelves with a non-abrasive cleaner. Vacuum condenser coils if present. Check seals and knobs; tighten or replace as needed to maintain CSA and NSF compliance.#@@#Additional Info#@#Evo America 10-0054-DCS-LP Affinity 30G cooking station delivers 37,638 BTU via liquid propane to a 30" black seasoned steel plancha with dual thermostatic zones, 225°–550° F, electronic ignition, stainless steel shelves, NSF certified, made in USA.#@@#General Info#@#Description #@#

Built to enhance outdoor operations with controlled, repeatable results, this commercial freestanding cooking station features a 30" seasoned steel plancha with precise thermostatic control, ideal for high-volume grilling tasks. Food service teams benefit from a spacious usable surface and dual-zone temperature control, allowing for searing, griddling, and gentle finishing without the need for equipment swaps. Operators will appreciate the electronic ignition, integrated tools, and NSF certification, which simplify service and compliance.

#@@# "Seasoned Steel Surface"#@#

The 30" diameter black seasoned steel plancha offers a broad contact area for consistent heat transfer across large batches. Chefs can sear proteins and caramelize produce with even browning, while the seasoned finish develops release properties that minimize sticking and cleaning time.

#@@# "Dual Temperature Zones"#@#

Two concentric temperature zones enable independent control of inner and outer cooking areas, allowing for simultaneous high-heat searing and lower-heat finishing. Kitchen staff can efficiently manage product flow on a single surface, reducing transfer steps and increasing throughput.

#@@# "Wide Temperature Range"#@#

Thermostatic controls regulate temperatures from 220°F to 550°F (121°–288° C), accommodating delicate warming and aggressive searing within the same unit. Teams can meet process requirements for various menu items without needing additional appliances.

#@@# "High Thermal Output"#@#

The unit generates 37,638 BTU to sustain rapid recovery under heavy load, ensuring stable surface temperatures during continuous service. Operators can minimize downtime between batches and maintain consistent cooking profiles throughout busy shifts.

#@@# "Durable Construction"#@#

Engineers designed the station with stainless steel shelving and robust components suitable for outdoor commercial use.

#@@#Delivery Details#@#

• Please ensure to handle the product with utmost care.

• Check if the product you have received has all the essential parts and accessories.

• Make sure to examine the product for damage before signing the delivery receipt.

• Contact customer service for delivery concerns.

• Delivery times may vary based on location.#@@#deliverynotes#@#NA#@@#Maintenance Guide#@#Inspect the cooking surface daily and remove debris with the supplied stainless steel scraper and spatulas to prevent carbon buildup. Clean with the provided kit after each service using manufacturer-approved solutions and warm water; rinse thoroughly and dry to prevent corrosion. Calibrate thermostatic controls monthly and verify temperature zones at multiple points. Lubricate moving parts quarterly, check seals and connectors for leaks, and document all maintenance.