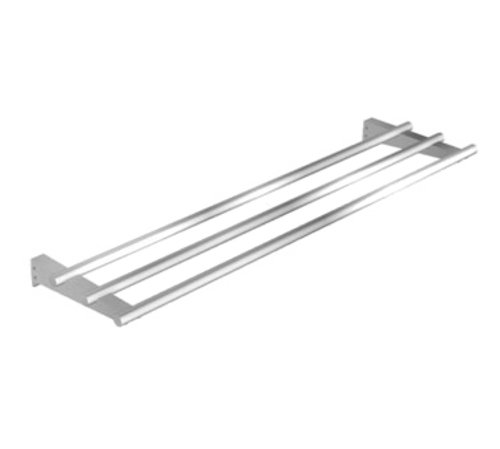

Stop sacrificing durability for convenience. This 3-rail stainless steel tray slide mounts on fixed brackets to provide consistent, heavy-duty support for high-volume service lines. It fits 32-inch openings while maintaining a compact 12-inch depth. Foodservice managers and facilities teams will appreciate the NSF certification and engineered geometry that stabilizes trays under continuous loading.

LongDescription#@#NA#@@#Cleaning Instructions#@#Unplug affected equipment and remove trays. Mix mild detergent with warm water at a safe ratio (use gallons or liters as needed) and apply with a soft cloth. Scrub stainless steel rails and brackets to remove grease; rinse thoroughly and dry to prevent corrosion. Clean vents and oven interiors to reduce fire risk. Inspect seals and fasteners; replace damaged parts. Schedule regular coil and rail cleaning to save energy, avoid breakdowns, and pass CSA and health inspections.#@@#Additional Info#@#Duke 3BTS-FX-32 tray slide mounts to fixed brackets and provides a 32" W x 12" D stainless steel 3-rail configuration for stationary tray handling, 1" tubular rails with end caps, NSF certified, 18.69 pounds, compatible with 31"–36" station widths.#@@#General Info#@#Description #@#

Stop sacrificing durability for convenience. This 3-rail stainless steel tray slide mounts on fixed brackets to provide consistent, heavy-duty support for high-volume service lines. It fits 32-inch openings while maintaining a compact 12-inch depth. Foodservice managers and facilities teams will appreciate the NSF certification and engineered geometry that stabilizes trays under continuous loading.

#@@# Three Rail Support#@#

Three stainless bars deliver linear support across the tray footprint, reducing sag and deflection during peak service. Engineers specified 1-inch diameter tubing to balance rigidity with minimal obstruction to tray insertion and removal.

#@@# Fixed Bracket Mount#@#

Stationary brackets lock the slide assembly to the counter structure, ensuring repeatable alignment and reducing lateral movement. Technicians will find the rigid mounting simplifies installation and eliminates the need for periodic retorquing common with adjustable systems.

#@@# Configured Width Range#@#

Designed to span widths from 31 inches to 36 inches, the unit installs in standard 32-inch openings while accommodating slight variance in counter cutouts. Installers can select the 32-inch model for exact fits or use the tolerance to streamline retrofits without cabinet modification.

#@@# Compact Depth Profile#@#

With a 12-inch depth, the slide minimizes intrusion into overhangs and service aisles while maintaining full tray support. Operators benefit from unobstructed access behind the line and reduced impact on passthrough clearance.

#@@# Sanitary Stainless Construction#@#

Fabrication in stainless steel resists corrosion, maintains structural integrity under repeated washdowns, and meets sanitation protocols for food contact areas. Supervisors will record fewer surface failures and lower lifecycle maintenance costs compared with plated or painted alternatives.

#@@#Delivery Details#@#

• Please ensure to handle the product with utmost care.

• Check if the product you have received has all the essential parts and accessories.

• Make sure to examine the product for damage before signing the delivery receipt.

• Contact customer service for delivery concerns.

• Delivery times may vary based on location.#@@#deliverynotes#@#NA#@@#Maintenance Guide#@#Inspect stainless steel rail surfaces weekly. Remove debris with a soft cloth and mild detergent to prevent corrosion. Rinse and dry immediately to avoid water marks. Lubricate contact points with food-safe silicone spray monthly for smooth tray movement. Verify bracket fasteners every 90 days and torque to manufacturer specs for alignment. Replace worn end caps or bent rails as needed. Record maintenance actions and part numbers, including 3BTS-FX-32 and CSA certifications, in service logs.