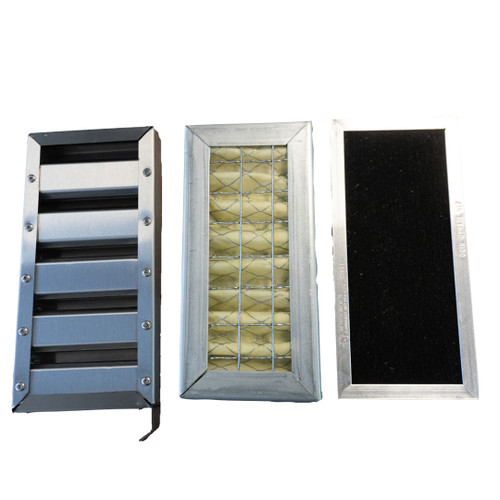

Stop compromising operational reliability for convenience. This stainless steel filter kit provides consistent particulate capture and simplifies routine maintenance for commercial kitchen exhaust systems. It helps teams maintain compliant airflow and minimize grease accumulation without frequent replacements. Operators will notice immediate improvements in filter handling time and predictable fitment across approved hood models.

LongDescription#@#NA#@@#Cleaning Instructions#@#Unplug and remove filters. Scrub Cadco VK-VH-FK VariKwik stainless steel filters with a mild detergent and warm water, using a soft brush to dislodge grease. Rinse thoroughly and air dry before reinstalling. Clean hood interiors and duct openings monthly to remove grease buildup and reduce fire risk. Inspect seals and fasteners; tighten or replace as needed. Maintain records to support CSA and health inspections, lower energy use, and prevent equipment failures.#@@#Additional Info#@#Cadco's VK-VH-FK VariKwik stainless steel filter kit offers durable, corrosion-resistant construction for commercial exhaust hoods.#@@#General Info#@#Description #@#

Stop compromising operational reliability for convenience. This stainless steel filter kit provides consistent particulate capture and simplifies routine maintenance for commercial kitchen exhaust systems. It helps teams maintain compliant airflow and minimize grease accumulation without frequent replacements. Operators will notice immediate improvements in filter handling time and predictable fitment across approved hood models.

#@@# Filtered Airflow#@#

This kit delivers targeted filtration media designed to trap grease and solid particulates while preserving duct static pressure. Engineering focuses on maintaining exhaust performance, ensuring system fans operate within specified RPM ranges and energy draw remains consistent.

#@@# Durable Construction#@#

Manufacturers construct the elements from corrosion-resistant stainless steel for continuous duty in high-humidity, high-temperature environments. Technicians report reduced deformation and longer in-service intervals compared with coated alternatives.

#@@# Standard Fitment#@#

Design adheres to established OEM dimensional tolerances to ensure drop-in compatibility with common commercial hoods and baffles. Installers reduce retrofit time and avoid custom modifications that interrupt kitchen schedules.

#@@# Service Efficiency#@#

Kits package multiple filter elements to streamline scheduled maintenance and stock rotation for facilities departments. Staff complete changeouts faster and log lower labor hours per maintenance cycle.

#@@# Compliance Ready#@#

Components comply with recognized fabrication and safety norms, including standards used in North American commercial kitchens, supporting inspection readiness. Facilities managers track audit documentation more easily when parts match listed specifications.

#@@# Lightweight Handling#@#

Each kit remains light enough for one-person handling while retaining structural rigidity during removal and cleaning.

#@@#Delivery Details#@#

• Please ensure to handle the product with utmost care.

• Check if the product you have received has all the essential parts and accessories.

• Make sure to examine the product for damage before signing the delivery receipt.

• Contact customer service for delivery concerns.

• Delivery times may vary based on location.#@@#deliverynotes#@#Upon confirmation of completed payment, Culinary Depot will ship and deliver the package.#@@#Maintenance Guide#@#Inspect filters weekly and replace when damage or excessive oil buildup reduces airflow. Clean stainless steel surfaces with a nonabrasive detergent and soft cloth to prevent corrosion. Remove grease with a degreaser rated for foodservice equipment; rinse thoroughly and dry to avoid residue. Verify fasteners and clips for secure fit; tighten as required. Document maintenance dates and parts replaced to maintain CSA compliance and operational reliability.