Streamlining mounting for high-volume donut operations can be achieved with a specialized bracket arm kit. This kit is designed for fryer attachment and enables secure integration with cut and fry systems used in busy production environments, providing operators with consistent alignment and dependable support that minimizes downtime and simplifies setup.

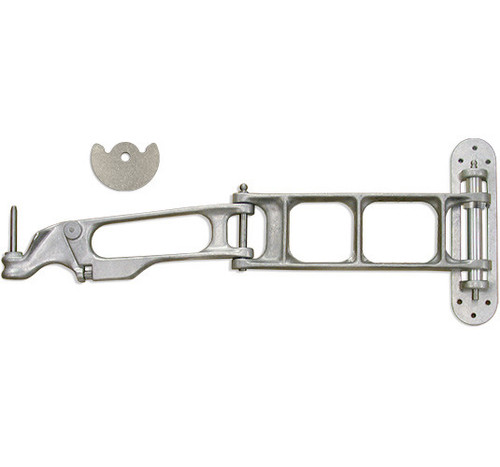

LongDescription#@#NA#@@#Cleaning Instructions#@#Unplug fryer and cool down. Remove bracket arm kit components; wipe metal parts with mild detergent, rinse, and dry. Degrease fryer surfaces and vents with a commercial degreaser; scrub grease and flush residue. Inspect brackets and column for wear or loose fasteners; tighten to specs. Clean nearby coils and filters to reduce fire risk and improve efficiency. Record cleaning in CSA log for inspections.#@@#Additional Info#@#Belshaw's N-1033 bracket arm kit includes a column and short extender arms for fryer mounting on Cut-N-Fry systems, offering rigid support, CSA-compliant construction, and corrosion-resistant finishes for food service operations.#@@#General Info#@#Description #@#

Streamlining mounting for high-volume donut operations can be achieved with a specialized bracket arm kit. This kit is designed for fryer attachment and enables secure integration with cut and fry systems used in busy production environments, providing operators with consistent alignment and dependable support that minimizes downtime and simplifies setup.

Short arms offer compact reach while ensuring stability for mounted attachments. Technicians can quickly install and position components, achieving repeatable placement that supports efficient workflow and reduces adjustments during peak production.

Components form a rigid support interface that resists flex under load. Managers benefit from fewer maintenance incidents because the assembly secures mounted tools and prevents misalignment that can interrupt service.

The kit aligns with cut and fry stations to integrate optional accessories, preserving workspace layout and keeping critical tools within ergonomic reach.

Parts are engineered to withstand continuous kitchen conditions and repeated handling. Maintenance teams inspect fewer wear points, which lowers replacement frequency and maintains consistent operation.

The kit occupies minimal space while providing full support capability, allowing operators to retain valuable counter area. Facility planners can optimize kitchen flow without sacrificing mounting strength or accessibility.

Design emphasizes straightforward assembly with clear attachment points, reducing installation time for in-house technicians. Procurement teams appreciate faster deployment and predictable fit with compatible mounting locations.

#@@#Delivery Details#@#

• Please ensure to handle the product with utmost care.

• Check if the product you have received has all the essential parts and accessories.

• Make sure to examine the product for damage before signing the delivery receipt.

• Contact customer service for delivery concerns.

• Delivery times may vary based on location.#@@#deliverynotes#@#NA#@@#Maintenance Guide#@#Use the Belshaw N-1033 Bracket Arm Mounting Kit to secure Cut-N-Fry units reliably. Inspect fasteners monthly and torque to manufacturer specifications; replace corroded hardware immediately. Clean mounting surfaces with a nonabrasive solvent and dry thoroughly before reassembly. Verify bracket alignment and levelness after every repositioning. Lubricate pivot points with food-safe lubricant sparingly. Retain CSA documentation and replacement part numbers for service records.