Stop compromising utility for sanitation. This floor trough delivers continuous, code-compliant drainage capacity across long runs while maintaining a clean, durable surface that resists corrosion and heavy daily use. Designed for foodservice and institutional environments, the unit connects directly to waste systems and reduces cleaning time with integrated grating and a pitched base.

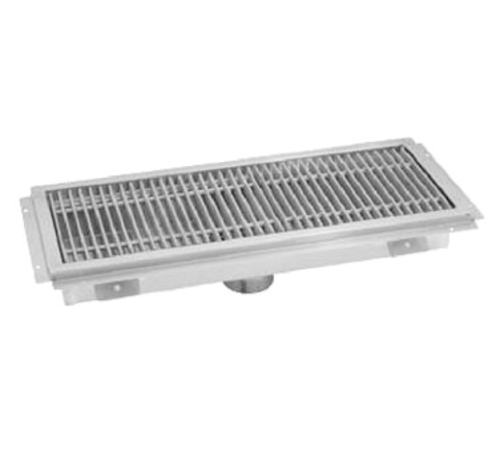

LongDescription#@#NA#@@#Cleaning Instructions#@#Unplug equipment near the trough before cleaning. Remove grates and wash with mild detergent and warm water, scrubbing bars with a nylon brush. Flush the trough with potable water, then apply a food-safe sanitizer as directed and allow contact time. Clear waste openings and inspect the 4" O.D. waste pipe for blockages. Dry stainless surfaces with a soft cloth to prevent spotting.#@@#Additional Info#@#Advance Tabco FTG-12120 floor trough is 120" W x 12" D x 4" H, made of 14 gauge 304 stainless steel with 3/16" x 1" bars; it has two drain openings, a 4" O.D. waste pipe, and is NSF certified, weighing 180 pounds for foodservice drainage.#@@#General Info#@#Description #@#

Stop compromising utility for sanitation. This floor trough delivers continuous, code-compliant drainage capacity across long runs while maintaining a clean, durable surface that resists corrosion and heavy daily use. Designed for foodservice and institutional environments, the unit connects directly to waste systems and reduces cleaning time with integrated grating and a pitched base.

#@@# Stainless Steel Build#@#

Fabricated from 14 Gauge 304 stainless steel, the trough provides corrosion resistance suited to wet, high-traffic areas. Maintenance crews benefit from a smooth finish that stands up to frequent washdowns and chemical cleaners.

#@@# Integrated Grating#@#

The unit includes stainless steel subway grating constructed from 3/16 inch by 1 inch bars to prevent large debris from entering the drain. Operators experience consistent surface drainage while staff perform less frequent grate removal for maintenance.

#@@# Pitched Toward Waste#@#

Engineers designed the trough with a pitch toward the waste openings to facilitate complete flow and minimize standing water. Cleaning teams find fewer residuals, improving hygiene and reducing slip hazards.

#@@# Dual Drain Openings#@#

The assembly ships with two drain openings and a 4 inch O.D. waste pipe with 3 inch length to provide flexible connection options. Plumbers install the system to meet site plumbing layouts without complex modifications.

#@@# Extended Length Capacity#@#

At 120 inches long and 12 inches deep with a 4 inch overall height, the trough suits long-line applications in kitchens, hospitals, and institutional facilities. Managers specify continuous coverage along prep zones to centralize drainage and improve workflow.

#@@# NSF Certified Design#@#

NSF certification confirms the product meets public health standards for foodservice drainage equipment. Procurement teams gain confidence in compliance and can document conformity during inspections.

#@@#Delivery Details#@#

• Please ensure to handle the product with utmost care.

• Check if the product you have received has all the essential parts and accessories.

• Make sure to examine the product for damage before signing the delivery receipt.

• Contact customer service for delivery concerns.

• Delivery times may vary based on location.#@@#deliverynotes#@#NA#@@#Maintenance Guide#@#Inspect grates weekly and remove debris to prevent pooling and odor. Use a soft brush and neutral detergent on 304 stainless steel, then rinse with potable water and dry with a lint-free cloth to avoid spotting. Flush drains with hot water monthly and check both drain openings for obstruction; clear with a plumbing snake when necessary. Verify floor pitch toward the 4" O.D. waste and tighten sanitary connections per CSA guidelines.