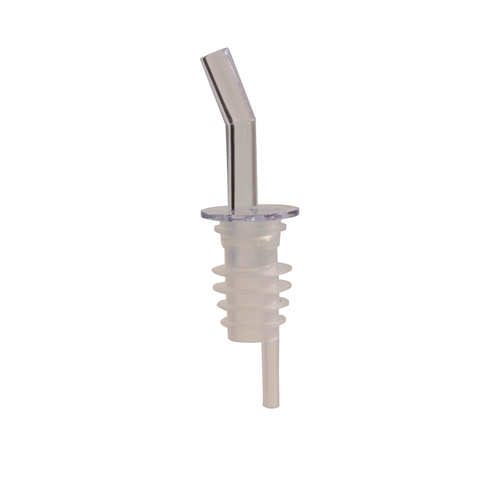

Stop wasting pours and slow service. This commercial-grade pourer transforms standard 750ml bottles into measured, consistent dispensers that enhance service speed and control costs. Designed for high-volume bars and food service operations, this clear plastic unit supports accurate 1.25 Oz. pours while withstanding continuous use.

LongDescription#@#NA#@@#Cleaning Instructions#@#Clean the Thunder Group PLPR125M pourer after each shift. Rinse with warm water, scrub spout and collar with a soft brush and mild detergent, then flush with potable water. Sanitize using an approved solution per CSA or local code, follow dwell time, and air dry on a clean rack. Regular cleaning prevents germ transfer on high-touch zones, supports health-code compliance, deters pests, and preserves plastic parts.#@@#Additional Info#@#Thunder Group PLPR125M clear plastic liquor pourer dispenses 1.25 Oz. per pour, fits 750ml bottles, and installs securely; SAN construction reduces breakage, staff pours precisely, and maintenance requires simple handwashing.#@@#General Info#@#Description #@#

Stop wasting pours and slow service. This commercial-grade pourer transforms standard 750ml bottles into measured, consistent dispensers that enhance service speed and control costs. Designed for high-volume bars and food service operations, this clear plastic unit supports accurate 1.25 Oz. pours while withstanding continuous use.

#@@# Flow Control#@#

Precision engineering produces a steady, calibrated 1.25 Oz. output that reduces overpouring and standardizes portioning. Operators achieve repeatable pours on every service cycle, tightening inventory control and improving cost forecasting.

#@@# Durable Construction#@#

SAN plastic resists cracking and absorbs impact better than brittle alternatives, enabling frequent handling without deformation. Managers preserve replacement budgets by specifying a material that performs under busy bar and banquet conditions.

#@@# Universal Fit#@#

A collar-equipped design fits standard 750ml bottles and adapts to most neck finishes used in backbar and mobile service. Bartenders experience seamless bottle swaps, accelerating lineup throughput during peak hours.

#@@# Clear Visibility#@#

Transparent components allow staff to inspect flow and cleanliness at a glance, minimizing contamination risk and simplifying sanitation checks. Supervisors verify pourer integrity without disassembly, saving time during shift turnovers.

#@@# Consistent Flow Rate#@#

A molded spout geometry maintains steady liquid dynamics across common product viscosities, ensuring a uniform stream and splash reduction. Teams reduce waste and maintain presentation standards across cocktails and pours.

#@@# Compact Packaging#@#

Each pack contains twelve units sized for tight storage in prep areas or service stations, enabling rapid replenishment during busy shifts. Purchasing departments manage stock with predictable pack counts and straightforward inventory math.

#@@#Delivery Details#@#

• Please ensure to handle the product with utmost care.

• Check if the product you have received has all the essential parts and accessories.

• Make sure to examine the product for damage before signing the delivery receipt.

• Contact customer service for delivery concerns.

• Delivery times may vary based on location.#@@#deliverynotes#@#NA#@@#Maintenance Guide#@#Inspect pourers before each shift and replace units showing cracks or deformation to prevent contamination and waste. Clean components after service with warm water and mild detergent; soak five minutes for dried residue, then rinse and air dry. Sanitize weekly using a food‑safe sanitizer per label directions, ensuring concentrations and contact times meet CSA or local code. Store dry in a sealed container to avoid dust and pest exposure.