Technicians have access to a comprehensive repair kit that includes essential components for restoring faucet performance efficiently. Designed for professional service teams, the kit consolidates necessary parts into one package for effective inventory management.

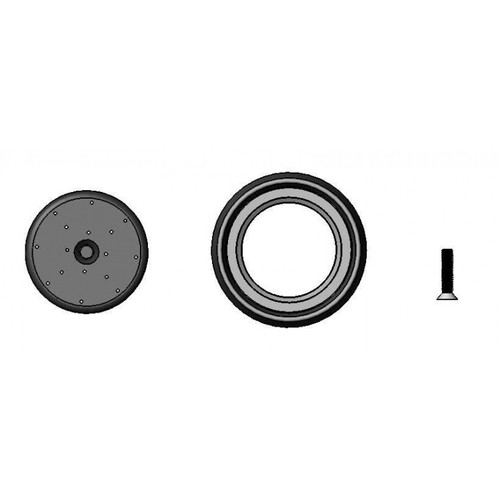

LongDescription#@#NA#@@#Cleaning Instructions#@#Unplug or shut water and gas before cleaning. Disassemble faucet trim and soak parts in warm, soapy water; scrub with a nylon brush to remove deposits. Rinse and dry all components; apply food-grade lubricant to moving parts. Wipe exterior with non-abrasive cleaner; avoid bleach on brass. Clean vents and coils to reduce fire risk and energy use. Inspect seals and replace worn parts using the T&S Brass 5SV-H-RK repair kit to maintain safety and pass CSA inspections.#@@#Additional Info#@#T&S Brass 5SV-H-RK Repair Kit offers OEM parts for pre-rinse faucets, restoring valve performance and preventing leaks. Technicians can install it quickly with common tools, and CSA compliance ensures material consistency for foodservice plumbing.#@@#General Info#@#Description #@#

Technicians have access to a comprehensive repair kit that includes essential components for restoring faucet performance efficiently. Designed for professional service teams, the kit consolidates necessary parts into one package for effective inventory management.

Technicians receive a precision component that restores smooth flow control and leak-free operation.

Field technicians install a seal to stop spray leakage and maintain consistent spray patterns under high use.

Service staff find all required components in the kit, simplifying repair calls and ensuring durability in humid kitchens.

Maintenance teams can quickly replace degraded seals using the assortment of sizes provided, restoring pressure integrity at multiple joint locations.

Plumbing professionals fit a component to prevent crossflow and maintain system backflow protection where local codes require.

Technicians follow a compact guide that outlines torque values and sequence to minimize installation errors, referencing CSA mounting and service practices for compliant field work.

#@@#Delivery Details#@#

• Please ensure to handle the product with utmost care.

• Check if the product you have received has all the essential parts and accessories.

• Make sure to examine the product for damage before signing the delivery receipt.

• Contact customer service for delivery concerns.

• Delivery times may vary based on location.#@@#deliverynotes#@#NA#@@#Maintenance Guide#@#Inspect the T&S Brass 5SV-H-RK repair kit monthly and replace worn seals and seats to prevent leaks. Use a calibrated torque wrench when reinstalling components to meet factory specifications and avoid overtightening. Flush lines after service to remove debris and verify flow rates in gallons per minute. Lubricate O-rings with a food-grade silicone lubricant and store spare parts in a dry, labeled container marked with CSA compliance where applicable.