Transform your packaging process with a powerful solution tailored for high-volume operations. This advanced system streamlines the sealing of trays, ensuring efficiency and consistency in every cycle. Built for durability and performance, this automatic packaging machine is an essential asset for any food service professional aiming to enhance productivity.

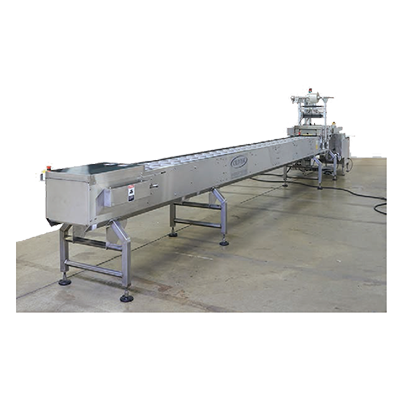

LongDescription#@#NA#@@#Cleaning Instructions#@#To keep your Oliver MX4 54-500 MX tray Lidder/Packaging System running smoothly, follow these cleaning steps. First, unplug the machine for safety. Use a damp cloth with mild soap to wipe down the conveyor and exterior surfaces. Pay special attention to the seal bar, cleaning it with a non-abrasive cleaner. Regularly check for grease buildup around the heating elements and remove it promptly to prevent hazards.#@@#Additional Info#@#The Oliver MX4 54-500 MX Tray Lidder/Packaging System features a 16' conveyor for efficient food packaging. Operating at 208 volts with a 30-amp draw, this automatic heat seal machine enhances productivity in the packaging process.#@@#General Info#@#Description #@#

Transform your packaging process with a powerful solution tailored for high-volume operations. This advanced system streamlines the sealing of trays, ensuring efficiency and consistency in every cycle. Built for durability and performance, this automatic packaging machine is an essential asset for any food service professional aiming to enhance productivity.

#@@# High-Volume Capacity#@#

This packaging system features a 16-foot conveyor, allowing for seamless handling of large quantities of products. The extended length accommodates multiple trays simultaneously, significantly increasing throughput. Consequently, businesses can meet high demand without sacrificing quality or speed.

#@@# Automatic Operation#@#

Engineered for ease of use, the automatic functionality minimizes the need for manual intervention. Operators can focus on other tasks while the machine efficiently seals trays, reducing labor costs and improving workflow. This feature is particularly beneficial in fast-paced environments where time is critical.

#@@# Versatile Seal Bar Length#@#

With a seal bar length ranging from 11 to 20 inches, this system adapts to various tray sizes, making it suitable for diverse packaging needs. Whether sealing small or large trays, the machine ensures a secure and airtight seal every time. This versatility enhances operational flexibility, accommodating different product types seamlessly.

#@@# Robust Construction#@#

Manufactured with high-quality materials, this packaging system withstands the rigors of daily use in busy kitchens. The durable design ensures longevity, reducing the need for frequent repairs or replacements. Investing in a robust machine translates to lower operational costs over time.

#@@# Energy Efficient#@#

Operating at 208 volts and 30 amps, this machine is designed to be energy efficient while delivering powerful performance. The efficient use of energy not only lowers utility costs but also aligns with sustainability goals.

#@@#Delivery Details#@#

• Please ensure to handle the product with utmost care.

• Check if the product you have received has all the essential parts and accessories.

• Make sure to examine the product for damage before signing the delivery receipt.

• Contact customer service for delivery concerns.

• Delivery times may vary based on location.#@@#deliverynotes#@#NA#@@#Maintenance Guide#@#To ensure optimal performance of the Oliver MX4 54-500 MX tray Lidder/Packaging System, conduct regular inspections of the conveyor. Clean the conveyor belt with a damp cloth to remove debris. Lubricate moving parts as per the manufacturer's guidelines for smooth operation. Monitor the heat seal bar for wear and replace it if needed for effective sealing. Verify that the voltage supply remains stable at 208 volts to avoid issues.