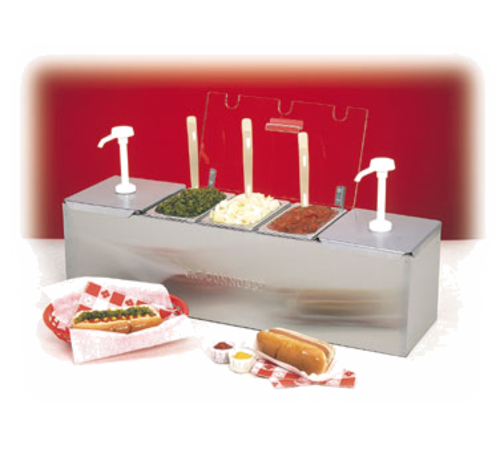

Handle high-traffic serving lines without sacrificing portion control or sanitation. This countertop condiment station combines modular stainless steel pans, positive-displacement pumps, and a sealed dry well to maintain organized, efficient service for cafeterias, concession stands, and quick-service kitchens. Buyers benefit from a compact footprint and durable construction that integrates with existing service lines while simplifying refill and sanitation procedures.

LongDescription#@#NA#@@#Cleaning Instructions#@#Unplug and empty the unit. Remove pans and pumps; wash with warm water and mild detergent. Scrub stainless surfaces with a non-abrasive pad, rinse, and sanitize food-contact parts per CSA or local rules. Clean pump nozzles and dry before reassembling. Vacuum vents and wipe dry well to remove debris and grease. Inspect seals and replace if damaged. Schedule weekly coil and deep-clean checks to reduce fire risk, avoid breakdowns, and keep energy use low.#@@#Additional Info#@#Nemco's 88100-CB-1 Roll-A-Grill® condiment station is 25.75" W x 8" D. It includes two 3 qt. stainless steel pans with pumps, one 6.1 qt. center pan, a plastic cover, dry well, ETL-certified stainless construction, and weighs 37 pounds.#@@#General Info#@#Description #@#

Handle high-traffic serving lines without sacrificing portion control or sanitation. This countertop condiment station combines modular stainless steel pans, positive-displacement pumps, and a sealed dry well to maintain organized, efficient service for cafeterias, concession stands, and quick-service kitchens. Buyers benefit from a compact footprint and durable construction that integrates with existing service lines while simplifying refill and sanitation procedures.

#@@# Pan Configuration#@#

Two 3-quart stainless steel pans flank a single 6.1-quart center pan to support multiple condiments and high-volume refill cycles. Operators can stage sauces, dressings, and relishes by volume to match menu demand and reduce refill frequency.

#@@# Metered Dispensing#@#

Two pump heads deliver controlled portions to eliminate overpouring and reduce waste under heavy throughput. Managers preserve consistency and predict ingredient cost targets through repeatable portion measures.

#@@# Dry Well Protection#@#

A dedicated dry well isolates motorized components from spills and drips to protect electrical parts and speed cleanups. Staff can perform routine surface cleaning without exposing pumps to liquid ingress.

#@@# Stainless Construction#@#

All exterior surfaces use stainless steel to resist corrosion and simplify sanitizing protocols under health code inspections. Supervisors maintain a professional service line aesthetic and achieve rapid wipe-down between shifts.

#@@# Compact Footprint#@#

At 25.75 inches wide and 8 inches deep, the station fits narrow countertops and busy pass windows while maximizing condiment capacity. Chefs retain counter space for plating and temperature control equipment.

#@@# Certified Reliability#@#

ETL certification confirms compliance with applicable safety and performance standards for commercial use. Facility managers reduce procurement risk and align with institutional equipment guidelines.

#@@#Delivery Details#@#

• Please ensure to handle the product with utmost care.

• Check if the product you have received has all the essential parts and accessories.

• Make sure to examine the product for damage before signing the delivery receipt.

• Contact customer service for delivery concerns.

• Delivery times may vary based on location.#@@#deliverynotes#@#NA#@@#Maintenance Guide#@#Clean pumps and pans daily to prevent bacterial buildup and ensure consistent flow. Remove lids and wash stainless steel pans with warm water and mild detergent; sanitize per facility protocol and air-dry. Lubricate pump plungers weekly with food-safe lubricant and inspect seals for wear; replace seals showing cracks. Verify unit remains level on the countertop and confirm secure pump alignment before service. Calibrate portion output monthly and document maintenance actions.