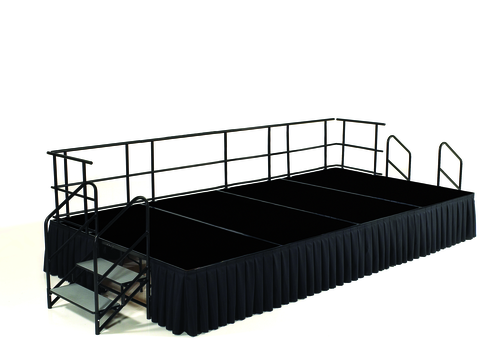

Build a durable performance platform that supports large events and frequent use while maintaining straightforward setup and code compliance. This modular rectangular stage group measures 192 inches by 240 inches with a 32-inch height and supports loads exceeding 200 pounds per square foot, enabling assemblies for presentations and performances with structural reliability. Designed for institutional and commercial environments since 1998, this unit balances capacity, portability, and certification requirements for food service, education, and hospitality facilities.

LongDescription#@#NPS® Stage Group, 192"W x 240"D x 32"H, 200+ lbs. per sq. ft. load capacity, 3/4" plywood deck, 16-gauge steel channel frame, folding legs, drop-in couplings, ANSI/BIFMA, MAS Green Certified#@@#Cleaning Instructions#@#Wipe stage deck with mild detergent and a soft mop; avoid abrasive pads. Sanitize high-touch zones like railings, access handles, and step edges using a hospital-grade disinfectant per label contact time. Inspect and tighten folding legs and drop-in couplings weekly; lubricate moving parts sparingly. Remove spills promptly to prevent staining and pest attraction. Regular cleaning prevents cross-contamination, preserves finish, and supports health-code compliance.#@@#Additional Info#@#National Public Seating SG483210 stage group measures 192" W x 240" D x 32" H and supports 200+ lbs per sq. ft.; 3/4" plywood deck mounts to a 16-gauge steel frame with folding legs, ANSI/BIFMA and MAS Green certified.#@@#General Info#@#Description #@#

Build a durable performance platform that supports large events and frequent use while maintaining straightforward setup and code compliance. This modular rectangular stage group measures 192 inches by 240 inches with a 32-inch height and supports loads exceeding 200 pounds per square foot, enabling assemblies for presentations and performances with structural reliability. Designed for institutional and commercial environments since 1998, this unit balances capacity, portability, and certification requirements for food service, education, and hospitality facilities.

#@@# Plywood Deck#@#

A 3/4-inch plywood deck delivers a stable walking surface and resists deflection under concentrated loads. Facilities staff will appreciate the rigid surface for staging equipment and foot traffic, and the deck accepts finish surfaces or stage skirts without structural modification.

#@@# Steel Channel Frame#@#

A 16-gauge steel channel frame provides lateral stiffness and resists torsion during live loading. Maintenance teams will find welding points and fastener access straightforward, reducing inspection time and simplifying routine checks.

#@@# Load Capacity#@#

A rated load capacity greater than 200 pounds per square foot ensures the platform supports dense occupant loads, instruments, and rigging gear. Event planners can configure the area for seating, standing crowds, or heavy equipment with predictable structural performance.

#@@# Folding Legs#@#

Folding legs speed deployment and storage while maintaining consistent support geometry when locked. Crew members will set up and dismantle the stage with fewer tools and reduced labor time compared with fixed leg systems.

#@@# Drop-In Couplings#@#

Drop-in couplings enable secure alignment between modules and permit rapid reconfiguration of stage layouts. Technical staff will achieve flush joins that minimize trip hazards and visible gaps for seamless stage surfaces.

#@@#Delivery Details#@#

• Please ensure to handle the product with utmost care.

• Check if the product you have received has all the essential parts and accessories.

• Make sure to examine the product for damage before signing the delivery receipt.

• Contact customer service for delivery concerns.

• Delivery times may vary based on location.#@@#deliverynotes#@#NA#@@#Maintenance Guide#@#Inspect the stage group weekly for loose fasteners and worn components. Tighten all bolts to specified torque values and replace damaged hardware immediately. Clean the 3/4" plywood deck with a neutral detergent; rinse and dry to prevent delamination. Lubricate folding leg hinges and drop-in couplings monthly with light machine oil. Verify frame alignment and load capacity markings before each setup; do not exceed 200 pounds per sq. ft.