Stop sacrificing control for simplicity. This inline flow control shut-off delivers precise liquid flow adjustments in draft systems while occupying minimal space. Operators gain immediate, repeatable throttling without complicated tools or lengthy downtime.

LongDescription#@#NA#@@#Cleaning Instructions#@#Unplug and depressurize the draft line before servicing the Micro Matic WD-020 0.25" in-line flow control shut off. Close upstream valves, remove the fitting, and flush the line with warm water to clear residue. Clean the valve body and seals with mild detergent and a soft brush; rinse thoroughly. Inspect seals and replace if worn. Reinstall, open valves slowly, check for leaks, and calibrate flow as needed to ensure safe, consistent dispensing.#@@#Additional Info#@#Micro Matic WD-020 0.25" in-line flow control shut off ensures precise beverage flow regulation for draft systems. Its durable design allows easy installation and maintenance, minimizing downtime for bars, restaurants, and kitchens.#@@#General Info#@#Description #@#

Stop sacrificing control for simplicity. This inline flow control shut-off delivers precise liquid flow adjustments in draft systems while occupying minimal space. Operators gain immediate, repeatable throttling without complicated tools or lengthy downtime.

#@@# Flow Adjustment#@#

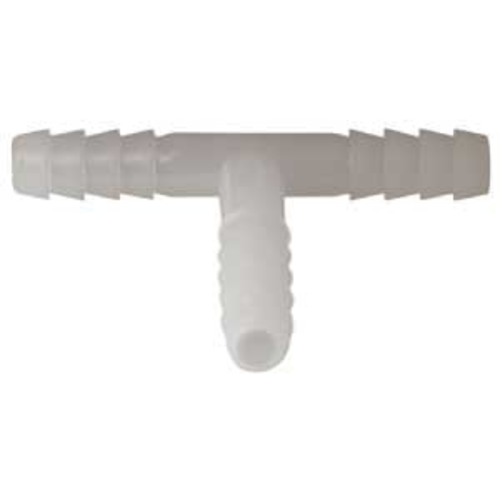

Installers achieve fine-tuned flow control with a 0.25-inch inline valve that sits directly in the line. Technicians can quickly dial back or open flow rates to balance pours across multiple lines, improving tap-to-tap consistency and reducing product waste.

#@@# Compact Inline Design#@#

Service staff benefit from a compact form factor that fits into tight runs and retrofit layouts. Engineers can place the unit near couplers or distributors without rerouting long sections, preserving system geometry and reducing material costs.

#@@# Tool-Free Operation#@#

Line workers operate the shut-off using a simple manual actuator, enabling rapid adjustments during peak service periods. Maintenance teams perform changes without specialized tools, cutting labor time for flow tuning and minimizing service interruptions.

#@@# Corrosion-Resistant Construction#@#

Brewpubs and bars receive durable service from materials selected for contact with carbonated liquids and cleaning agents. Managers can expect extended component life when the valve resists common corrosive elements used in draft system cleaning regimes.

#@@# Precision Metering#@#

Quality control staff obtain consistent pour volumes through repeatable metering increments that stabilize head retention and presentation. Purchasing managers reduce overpour losses and control inventory more accurately when each line maintains target yield.

#@@# Service Compatibility#@#

Operations integrate the valve into standard draft assemblies used in commercial settings, including connections near distributors and couplers.

#@@#Delivery Details#@#

• Please ensure to handle the product with utmost care.

• Check if the product you have received has all the essential parts and accessories.

• Make sure to examine the product for damage before signing the delivery receipt.

• Contact customer service for delivery concerns.

• Delivery times may vary based on location.#@@#deliverynotes#@#NA#@@#Maintenance Guide#@#Inspect the Micro Matic WD-020 inline flow control weekly for leaks and corrosion. Use food‑grade lubricant on moving parts and tighten fittings to specified torque values. Flush lines with warm water and approved sanitizer after heavy use; purge air to stabilize flow. Replace O‑rings and seals at first sign of wear. Record maintenance dates and measured flow rates in gallons or liters to ensure consistent dispensing and reduce downtime.