Stop wasting time and risking contamination during cleaning cycles. This innovative cleaning cap provides controlled flow and secure seals for both portable and in-place cleaning, enabling operators to maintain tap lines efficiently while preserving product quality and reducing downtime. Designed for professional dispensing systems, the cap integrates seamlessly with standard fittings to support routine sanitation protocols in high-traffic environments.

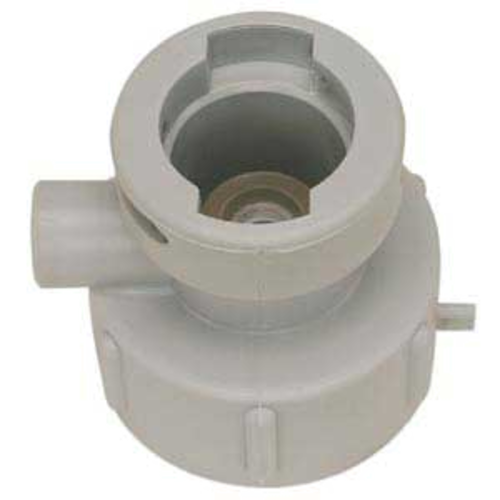

LongDescription#@#NA#@@#Cleaning Instructions#@#Wipe cap and fittings after each shift using mild detergent and a soft cloth. Rinse with potable water and flush lines per manufacturer schedule. Use approved sanitizer on high-touch zones like handles and covers; contact time must meet label instructions. Inspect seals and threads for wear; replace damaged parts immediately. Regular cleaning prevents germ transfer between front- and back-of-house, supports health-code compliance, deters pests, and preserves fittings' service life.#@@#Additional Info#@#Micro Matic M801184KS S System cleaning cap enables efficient cleaning of beverage lines for on-premise operations. It fits standard Micro Matic components, resists corrosion, meets CSA requirements, and simplifies sanitation for staff.#@@#General Info#@#Description #@#

Stop wasting time and risking contamination during cleaning cycles. This innovative cleaning cap provides controlled flow and secure seals for both portable and in-place cleaning, enabling operators to maintain tap lines efficiently while preserving product quality and reducing downtime. Designed for professional dispensing systems, the cap integrates seamlessly with standard fittings to support routine sanitation protocols in high-traffic environments.

#@@# Durable Seal#@#

This cap features a reinforced sealing surface to prevent leaks during pressurized cleaning cycles. Technicians achieve consistent line integrity, minimizing fluid loss and preventing external contamination effectively.

#@@# Universal Compatibility#@#

Engineered to interface with a wide range of system fittings, the cap accepts common connectors and cleaning adapters. Staff members save time by utilizing one cap across multiple locations, streamlining inventory and simplifying training processes.

#@@# Pressure Control#@#

The design supports controlled flow rates during chemical circulation and rinse phases to ensure thorough internal cleaning. Operators maintain required contact times for detergents and sanitizers, enhancing microbial removal without overpressurizing lines.

#@@# Portable and Fixed Use#@#

Manufacturers included features that accommodate both handheld cleaning rigs and in-line sanitation setups, allowing facilities to switch between on-site service and permanent cleaning stations. Maintenance teams can adapt the cap to varied workflows without needing additional specialty parts.

#@@# Chemical Resistance#@#

Materials selected resist common alkaline and acidic cleaning agents used in dispensing system sanitation, maintaining dimensional stability and seal performance over repeated cycles. Managers can extend service intervals and reduce replacement frequency effectively.

#@@#Delivery Details#@#

• Please ensure to handle the product with utmost care.

• Check if the product you have received has all the essential parts and accessories.

• Make sure to examine the product for damage before signing the delivery receipt.

• Contact customer service for delivery concerns.

• Delivery times may vary based on location.#@@#deliverynotes#@#Upon confirmation of the completed payment, Culinary Depot will ship and deliver the Micro Matic M801184KS Cleaning Cap.#@@#Maintenance Guide#@#Maintain the Micro Matic M801184KS S System Portable and In Place Cleaning Cap by flushing lines after each service with manufacturer-approved cleaner to prevent biofilm. Inspect seals and threads for wear and replace damaged items immediately. Disassemble removable parts weekly and soak in warm solution, then air-dry on a clean surface. Calibrate flow and pressure monthly to ensure proper purge. Document each maintenance cycle and retain records for CSA compliance.