Stop wasting time on inefficient cleaning steps. These portable cleaning caps streamline draft line maintenance, keeping lines sealed and ready for routine sanitation while reducing labor and service interruptions. Many operations will sustain product quality and minimize contamination risks with an accessory designed for frequent use in busy service environments.

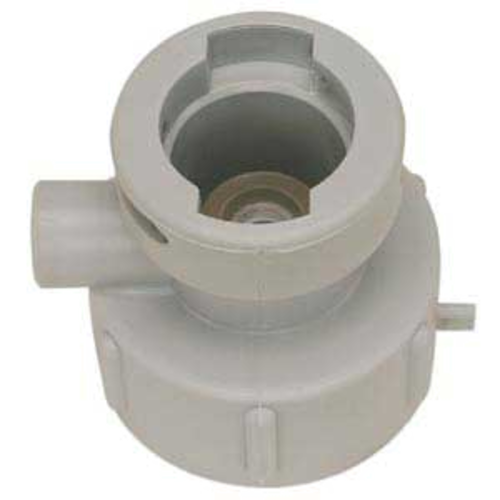

LongDescription#@#NA#@@#Cleaning Instructions#@#Wipe caps with a soft cloth and a mild detergent solution, rinse in clean water, and air dry. Disassemble removable parts and brush internal surfaces to remove beer residue. Sanitize with an approved surface sanitizer following label contact time, then reassemble. Cleaning prevents transfer of Norovirus and cold viruses from high-touch zones, maintains appearance that shapes customer perception, ensures visible compliance with health codes, and reduces pest attraction.#@@#Additional Info#@#Micro Matic M103414 back plate cleaning caps enable quick cleaning of draft beer fittings. Technicians install caps, circulate sanitizer, and flush lines to maintain hygiene and reduce contamination risks in high-volume beverage programs.#@@#General Info#@#Description #@#

Stop wasting time on inefficient cleaning steps. These portable cleaning caps streamline draft line maintenance, keeping lines sealed and ready for routine sanitation while reducing labor and service interruptions. Many operations will sustain product quality and minimize contamination risks with an accessory designed for frequent use in busy service environments.

#@@# Back Plate#@#

Designed to anchor cleaning caps securely, the back plate provides a stable mounting surface that prevents slippage during pressurized cleaning cycles. Operators will rely on its solid alignment to maintain consistent contact between cap and faucet, reducing the chance of leaks or misalignment during flush procedures.

#@@# Portable Cleaning Caps#@#

Engineered for in-place use, the cleaning caps allow technicians to clean fittings without fully disassembling assemblies, cutting downtime and simplifying sanitation protocols. Staff will perform regular line cleaning faster while retaining proper sealing to channel cleaning solution through fittings effectively.

#@@# Durable Construction#@#

Manufactured to endure repeated handling and chemical exposure, the product resists deformation under typical cleaning pressures used in draft systems. Facilities will benefit from longer service life and lower replacement frequency under routine maintenance schedules.

#@@# Compatibility Assurance#@#

Designed to work with common draft tap assemblies, the cleaning caps adapt to standard coupling geometries to provide reliable sealing across many system configurations. Maintenance teams will reduce inventory complexity by using caps that accommodate multiple faucet types.

#@@# Compliance Ready#@#

Fabricated to meet industry cleaning practices, the accessory supports standardized cleaning procedures and helps operations maintain sanitary dispensing conditions. Managers will document consistent cleaning cycles that align with health protocols and internal QA programs.

#@@#Delivery Details#@#

• Please ensure to handle the product with utmost care.

• Check if the product you have received has all the essential parts and accessories.

• Make sure to examine the product for damage before signing the delivery receipt.

• Contact customer service for delivery concerns.

• Delivery times may vary based on location.#@@#deliverynotes#@#NA#@@#Maintenance Guide#@#Use a soft brush and warm water to remove deposits from the Micro Matic M103414 back plate and portable cleaning caps, avoiding solvents that degrade seals. Inspect caps for cracks and replace when wear appears. Sanitize components with a food-safe sanitizer at manufacturer-recommended concentration and contact time. Rinse thoroughly and air dry. Verify fit and alignment before reinstalling. Document cleaning frequency and results for CSA compliance.