Stop wasting time with inconsistent line cleaning. This single flusher cleaning cup delivers targeted cleaning for draft systems, reduces manual scrubbing, and integrates with common ball lifter assemblies to speed maintenance routines. Designed for professional pour systems, it fits both D and S configurations to simplify inventory and service training.

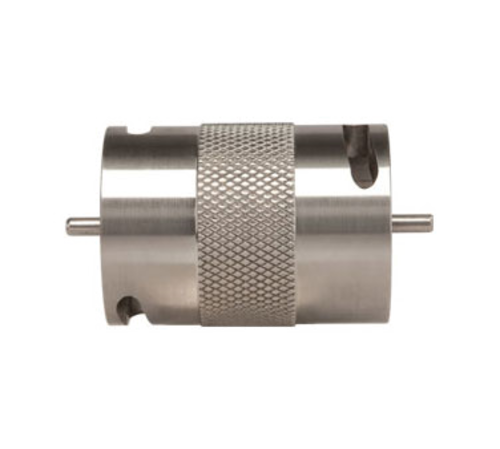

LongDescription#@#NA#@@#Cleaning Instructions#@#Use this cleaning cup after each service. Rinse with warm water, scrub internal surfaces with a soft brush and mild detergent, then flush through the draft line per manufacturer protocols. Sanitize weekly with an approved solution at labeled concentration, rinse thoroughly, and air dry. Clean high-touch items like faucet handles and tap exteriors to prevent cross-contamination, deter pests, preserve materials, and support health-code compliance.#@@#Additional Info#@#Micro Matic FT108-BL Single Flusher Cleaning Cup fits "D" and "S" draft systems with a ball lifter for targeted line and faucet cleaning.#@@#General Info#@#Description #@#

Stop wasting time with inconsistent line cleaning. This single flusher cleaning cup delivers targeted cleaning for draft systems, reduces manual scrubbing, and integrates with common ball lifter assemblies to speed maintenance routines. Designed for professional pour systems, it fits both D and S configurations to simplify inventory and service training.

#@@# Single Flusher#@#

Designed to operate with D and S system configurations, the flusher cups provide a direct pathway for cleaning solution to reach critical flow paths. Technicians achieve repeatable results quickly, reducing dwell time during line maintenance.

#@@# Ball Lifter Compatible#@#

Engineers included ball lifter compatibility so the cup engages and seals properly with standard assemblies, preventing backflow and ensuring concentrated contact with valve surfaces. Operators maintain sanitary conditions while minimizing solution waste.

#@@# Durable Construction#@#

Manufactured from robust materials, the cup resists cracking and deformation under repeated use and chemical exposure. Maintenance teams extend service life and preserve form under routine cleaning cycles.

#@@# Precise Fitment#@#

Manufacturers engineered the geometry to align with tap fittings, producing reliable sealing and consistent flushing pressure. Facility managers standardize parts across multiple tap models, reducing spare part complexity.

#@@# Easy Serviceability#@#

Technicians install and remove the cup without tools, accelerating sanitation tasks and shortening downtime windows. Service crews return systems to operation faster while sustaining compliance with cleaning schedules.

#@@# Chemical Flow Control#@#

Design channels concentrate cleaning agents where residues accumulate, improving removal of organics and deposits in draft lines. Quality control personnel document improved line cleanliness with fewer repeat passes.

#@@#Delivery Details#@#

• Please ensure to handle the product with utmost care.

• Check if the product you have received has all the essential parts and accessories.

• Make sure to examine the product for damage before signing the delivery receipt.

• Contact customer service for delivery concerns.

• Delivery times may vary based on location.#@@#deliverynotes#@#NA#@@#Maintenance Guide#@#Inspect the Micro Matic FT108-BL Single Flusher Cleaning Cup weekly for residue and wear. Remove buildup by soaking the cup in warm water with a neutral detergent, then scrub with a soft brush to preserve seal integrity. Rinse thoroughly and air dry to prevent corrosion. Lubricate movable parts with food-grade lubricant every month. Replace the cup if cracks appear or if flow diminishes. Record maintenance actions per CSA guidelines.