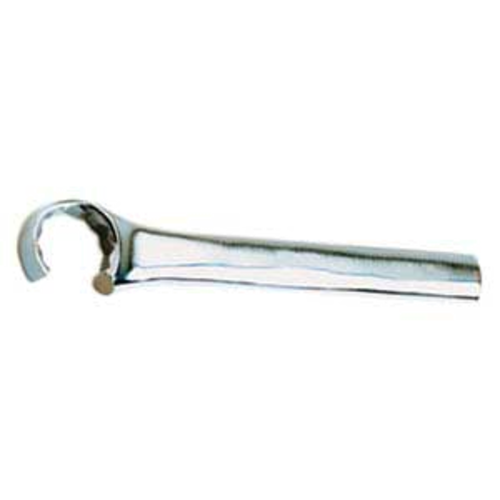

Stop compromising access for control. This precision parallel tower wrench allows technicians to quickly and reliably remove and install 1.07-inch nuts, significantly reducing service time on draft lines and tap towers. Designed specifically for beer system maintenance, the tool ensures an exact fit and provides strong leverage, enabling crews to complete turnaround work without damaging fittings or cosmetic finishes.

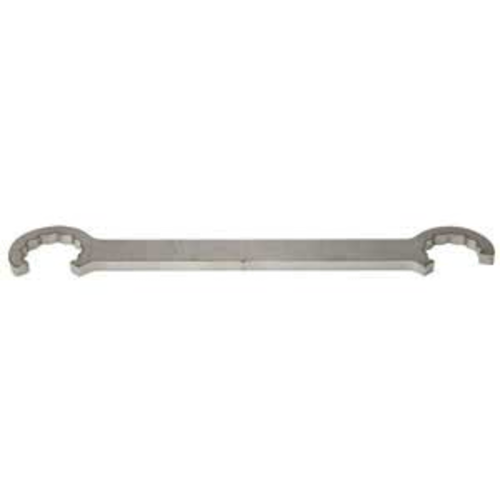

LongDescription#@#NA#@@#Cleaning Instructions#@#Unplug and remove the faucet components. Scrub the tower wrench and surrounding fittings with a mild detergent solution and a soft brush to remove grease and residue. Rinse with clean water and dry with a lint-free cloth. Inspect 1.07" nuts and seals; replace worn parts. Clean vents and nearby surfaces weekly to prevent grease buildup and fire risk. Record cleaning dates to support CSA inspections and extend equipment life.#@@#Additional Info#@#Micro Matic DTW4136 tower wrench fits 1.07" nuts, offers precise torque control for draft beer towers, reduces downtime with durable steel, ensures faucet alignment, and meets CSA requirements for commercial use.#@@#General Info#@#Description #@#

Stop compromising access for control. This precision parallel tower wrench allows technicians to quickly and reliably remove and install 1.07-inch nuts, significantly reducing service time on draft lines and tap towers. Designed specifically for beer system maintenance, the tool ensures an exact fit and provides strong leverage, enabling crews to complete turnaround work without damaging fittings or cosmetic finishes.

#@@# Parallel Head#@#

The parallel head aligns perfectly with 1.07-inch nuts, delivering uniform contact across flats. Technicians experience reduced slippage and minimized rounding when applying torque, which enhances first-pass service success.

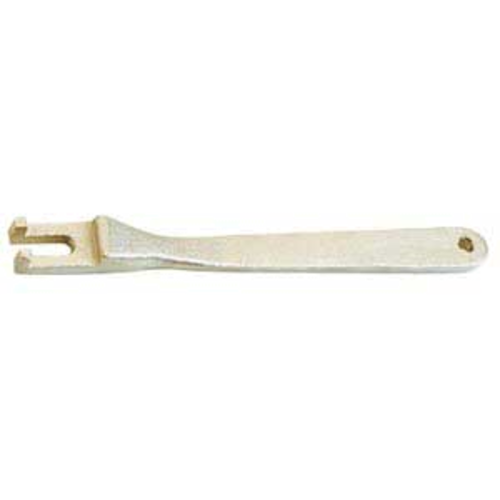

#@@# Durable Construction#@#

Manufacturers use high-strength alloy for torsional resistance and longevity. Field staff encounter fewer tool failures and replacement cycles, which lowers operating expenses for maintenance programs.

#@@# Ergonomic Grip#@#

Engineers have contoured the handle for secure hand placement and improved torque transfer. Workers experience less fatigue during repeated removals and installations on busy service days.

#@@# Exact Fit Specification#@#

Design tolerances match 1-1/16 inch nominal sizing to ensure consistent engagement with tower nuts and related fittings. Service teams achieve predictable torque application and preserve threads and plated surfaces during routine adjustments.

#@@# Compact Profile#@#

The wrench's compact dimensions allow access to confined spaces behind shrouds and inside rail assemblies. Technicians can complete adjustments in tight wells without disassembling adjacent components, saving valuable labor minutes per site visit.

#@@# Field Service Ready#@#

The finish resists corrosion in wet cellars and behind bars where condensation and cleaning chemicals come into contact with tools. Maintenance departments maintain inventory confidence because the wrench withstands typical environmental exposure in draft system areas.

#@@#Delivery Details#@#

• Please ensure to handle the product with utmost care.

• Check if the product you have received has all the essential parts and accessories.

• Make sure to examine the product for damage before signing the delivery receipt.

• Contact customer service for delivery concerns.

• Delivery times may vary based on location.#@@#deliverynotes#@#NA#@@#Maintenance Guide#@#Inspect the Micro Matic DTW4136 tower wrench before each service interval and verify fit with 1.07" nuts. Clean tool with a lint-free cloth and isopropyl alcohol; avoid solvents that degrade finishes. Lubricate moving interfaces lightly with food-safe lubricant every three months. Store wrench dry in a labeled case to prevent corrosion. Calibrate torque procedures periodically and replace the wrench if threads or jaws show deformation or excessive wear.