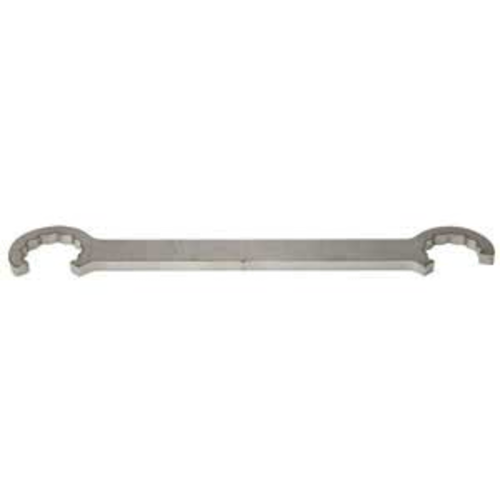

Stop wasting time struggling with ill-fitting tools. This dual-sided tower wrench delivers precise engagement with both 1-inch and 1.0625-inch nuts, enabling fast, reliable service on draft lines and tap towers. Operators can tighten and loosen fittings with controlled torque and repeatable alignment, reducing downtime during maintenance and installation work.

LongDescription#@#NA#@@#Cleaning Instructions#@#Unplug equipment and remove fittings. Scrub the wrench and tower fittings with a mild detergent solution and a soft brush to remove grease and debris. Rinse thoroughly with clean water and dry with a lint-free cloth. Inspect nuts and seals for wear; replace damaged parts. Clean vents and coils monthly to prevent fires and reduce energy use. Maintain records to meet CSA and health inspections and to extend equipment life.#@@#Additional Info#@#Micro Matic's D8ES-CB dual-sided tower wrench fits 1" and 1.06" nuts, allowing quick installation and removal of tap tower fittings. The forged steel design enhances torque transfer and resists wear, ensuring foodservice safety and longevity.#@@#General Info#@#Description #@#

Stop wasting time struggling with ill-fitting tools. This dual-sided tower wrench delivers precise engagement with both 1-inch and 1.0625-inch nuts, enabling fast, reliable service on draft lines and tap towers. Operators can tighten and loosen fittings with controlled torque and repeatable alignment, reducing downtime during maintenance and installation work.

#@@# Dual Size Engagement#@#

This wrench accepts 1-inch and 1.0625-inch hex nuts on opposing faces, allowing technicians to switch tasks without changing tools. Reduced tool changes speed service calls and keep repair times consistent across a range of tap tower hardware.

#@@# Robust Metal Construction#@#

Manufacturers design the unit from hardened metal to resist deformation under frequent torque application. Field crews will maintain correct nut profiles longer, lowering replacement frequency and preserving fitting integrity.

#@@# Compact Service Geometry#@#

Engineers sized the wrench for tight tower spaces and crowded backbars, enabling technicians to access recessed nuts without removing adjacent components. Faster access translates to less disruption during routine inspections and calibrations.

#@@# Precise Fit Tolerance#@#

Machining tolerances ensure snug contact with nut flats, minimizing rounding and slippage during force application. Maintenance teams experience fewer stripped fittings and achieve secure seals that prevent leaks.

#@@# Dual Function Efficiency#@#

Designers placed two commonly used sizes on one tool to consolidate kits and reduce inventory. Purchasing managers will lower tool counts and streamline technician training while maintaining on-site readiness.

#@@# Field Ready Finish#@#

Surface treatment resists corrosion from line splashes and humid cellar environments, maintaining tool performance over repeated use. Service personnel will find cleaning and handling simple, preserving long-term utility.

#@@#Delivery Details#@#

• Please ensure to handle the product with utmost care.

• Check if the product you have received has all the essential parts and accessories.

• Make sure to examine the product for damage before signing the delivery receipt.

• Contact customer service for delivery concerns.

• Delivery times may vary based on location.#@@#deliverynotes#@#NA#@@#Maintenance Guide#@#Use the Micro Matic D8ES-CB tower wrench to effectively tighten and loosen 1" and 1.06" nuts with controlled torque for optimal performance. It is crucial to inspect the tool before each shift for any signs of deformation or wear, and discard it if it appears compromised in any way. Clean the wrench with a mild detergent and dry it immediately to prevent any potential corrosion. Additionally, lubricate pivot points quarterly with a food-safe lubricant to ensure smooth operation.