Stop compromising seal integrity for speed. This 4-inch tower gasket delivers a precise, durable seal for high-volume draft installations, supporting consistent pressure and reducing leaks during peak service. Installers and service managers gain a repeatable component that fits standard 4-inch O.D. towers and integrates seamlessly with existing tap hardware.

LongDescription#@#NA#@@#Cleaning Instructions#@#Replace towers gasket every 6–12 months or when you see wear. Remove faucet components, lift out the 4" O.D. gasket, inspect for cracks and hardening. Clean the seal seat with a food-safe degreaser and soft brush, rinse with potable water, dry completely. Fit the new Micro Matic D16-4 gasket evenly, reassemble fittings, and test for leaks. Regular cleaning prevents contamination, reduces fire risk from grease, lowers energy use, and helps pass CSA inspections.#@@#Additional Info#@#Micro Matic D16-4 4" O.D. towers gasket seals draft beer tap towers. Made from durable elastomer, it resists beer acids and cleaning chemicals. Fits 4" towers, installs quickly, and meets CSA safety specs.#@@#General Info#@#Description #@#

Stop compromising seal integrity for speed. This 4-inch tower gasket delivers a precise, durable seal for high-volume draft installations, supporting consistent pressure and reducing leaks during peak service. Installers and service managers gain a repeatable component that fits standard 4-inch O.D. towers and integrates seamlessly with existing tap hardware.

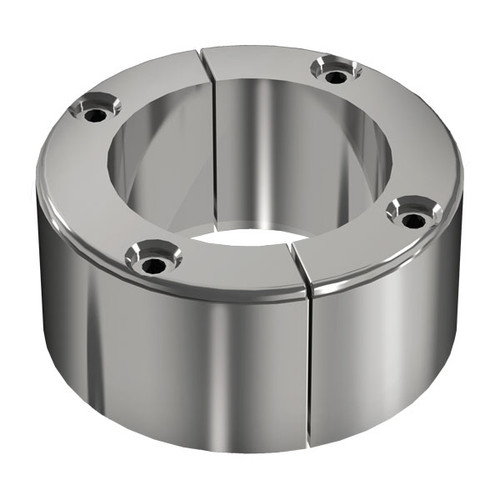

#@@# Durable Ring#@#

Installers receive a gasket molded from resilient elastomer designed to withstand repeated assembly and disassembly. The ring maintains sealing pressure under typical cellar temperatures and effectively prevents product loss at connection points.

#@@# Exact Fit#@#

Technicians obtain a consistent 4-inch outer diameter that matches industry tower openings for predictable alignment. This exact fit reduces installation time and minimizes the need for shims or adjustments, ensuring a smooth setup process.

#@@# Pressure Retention#@#

Operators benefit from sustained pressure control across the dispense line, which preserves carbonation and reduces foam. The gasket limits microleaks that can escalate service interruptions and product waste, enhancing overall efficiency.

#@@# Corrosion Resistance#@#

Maintenance teams appreciate a material choice that resists corrosion from humid cellar conditions and common cleaning chemistries. This resistance extends service life and lowers the frequency of replacements, contributing to long-term reliability.

#@@# Simple Replacement#@#

Service staff can replace the gasket quickly during routine maintenance without the need for specialized tools, effectively cutting downtime during shift changeovers. This straightforward swap supports preventive schedules and enhances inventory predictability.

#@@# Compatibility Range#@#

Purchasers find broad compatibility with standard tap towers and draft components used in restaurants, bars, institutions, and hospitality accounts.

#@@#Delivery Details#@#

• Please ensure to handle the product with utmost care.

• Check if the product you have received has all the essential parts and accessories.

• Make sure to examine the product for damage before signing the delivery receipt.

• Contact customer service for delivery concerns.

• Delivery times may vary based on location.#@@#deliverynotes#@#NA#@@#Maintenance Guide#@#Clean the Micro Matic D16-4 4" O.D. towers gasket after each shift by flushing with warm water and a food-safe detergent to remove yeast and sediment. Inspect the gasket weekly for cuts, hardening, or compression set and replace immediately if defects appear. Sanitize with an approved sanitizer at recommended concentrations; follow contact times specified by the sanitizer manufacturer. Lubricate with a food-grade silicone grease to maintain seal flexibility and ease of installation.