Stop compromising line integrity for convenience. This glycol-only trunk line delivers consistent chilled circulation across four dispensing runs, engineered for continuous service in high-demand draft systems. Operators gain predictable thermal control and simplified maintenance while supporting centralized refrigeration strategies.

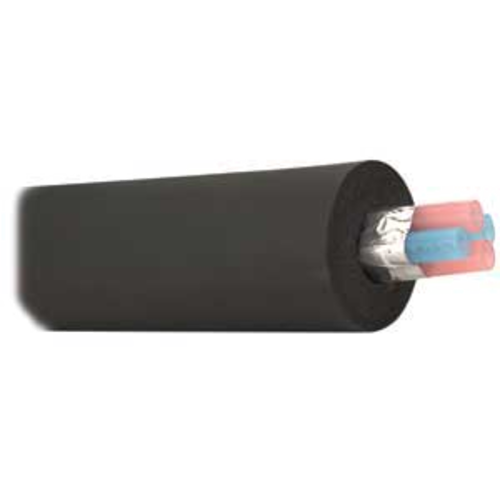

LongDescription#@#NA#@@#Cleaning Instructions#@#Unplug glycol trunk line and drain into an approved container. Flush lines with manufacturer-recommended solution, using 1–2 gallons per line. Scrub fittings and outer housing with a soft brush and mild detergent. Rinse thoroughly with potable water. Inspect seals and clamps; replace worn parts. Dry all surfaces before refilling glycol. Regular cleaning prevents contamination, reduces fire risk, lowers energy use, and helps pass CSA and health inspections.#@@#Additional Info#@#Micro Matic CDI-GLY-4 routes glycol to four draft lines for beverage temperature control, with durable tubing, quick-connect fittings, and compatibility with tap towers; technicians ensure consistent product quality.#@@#General Info#@#Description #@#

Stop compromising line integrity for convenience. This glycol-only trunk line delivers consistent chilled circulation across four dispensing runs, engineered for continuous service in high-demand draft systems. Operators gain predictable thermal control and simplified maintenance while supporting centralized refrigeration strategies.

#@@# Flow Capacity#@#

Designed for four parallel runs, the trunk line routes glycol through discrete passages to maintain consistent temperature along each run. Installers receive clear routing that reduces pressure drop and preserves chilled fluid flow across long runs.

#@@# Glycol Compatibility#@#

Manufactured for glycol-only service, the construction resists swelling and degradation from common propylene and ethylene glycol formulas. Technicians can rely on material compatibility to extend hose life and prevent contaminant transfer.

#@@# Durable Construction#@#

Engineered with robust materials, the trunk line withstands the mechanical stresses of commercial draft systems and repeated handling during installation. Maintenance crews observe fewer failures and lower replacement frequency under regular operating cycles.

#@@# Thermal Control Precision#@#

The multi-line trunk minimizes thermal gradients between source and endpoints, keeping dispensing lines within target temperature windows. Beverage quality remains consistent, and cooling loads distribute evenly across the refrigeration circuit.

#@@# Installation Efficiency#@#

Modular layout and four-line configuration simplify field termination and reduce labor time when connecting multiple towers or faucets. Project managers benefit from shorter install windows and predictable commissioning steps.

#@@# Serviceability Design#@#

Accessible geometry and standardized fittings permit rapid inspection and section replacement without system-wide shutdown. Facility teams perform localized repairs quickly, reducing downtime and preserving service continuity.

#@@#Delivery Details#@#

• Please ensure to handle the product with utmost care.

• Check if the product you have received has all the essential parts and accessories.

• Make sure to examine the product for damage before signing the delivery receipt.

• Contact customer service for delivery concerns.

• Delivery times may vary based on location.#@@#deliverynotes#@#NA#@@#Maintenance Guide#@#Mount glycol trunk lines yearly for inspection and cleaning. Disconnect service lines, flush each with the recommended glycol solution, and circulate for the specified time to remove biofilm and sediment. Rinse with potable water until pH is neutral. Inspect fittings, clamps, and insulation for wear; replace damaged parts immediately. Verify flow rates and temperature delta with calibrated gauges and log results. Schedule quarterly visual checks and annual pressure tests per CSA guidelines.