Stop wasting time on temporary solutions. This stainless steel cleaning cup for flusher series installs quickly and performs reliably in high-use bar and kitchen environments, delivering consistent cleaning action for draft tap systems. Operators gain repeatable sanitation results and rapid turnaround during peak service with a compact, serviceable design.

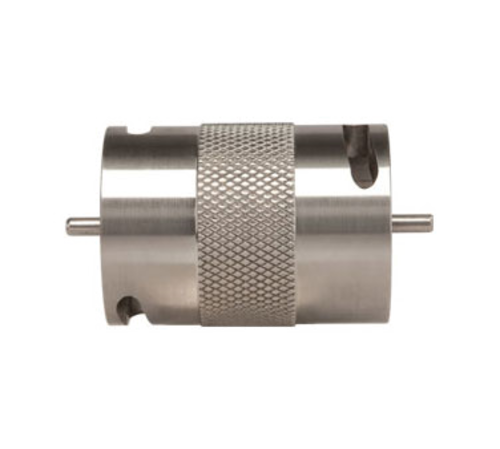

LongDescription#@#NA#@@#Cleaning Instructions#@#Unplug and remove the cleaning cup. Rinse with warm water to remove loose debris. Prepare a mild detergent solution using gallons or liters as needed. Scrub stainless steel surfaces with a soft brush; avoid abrasive pads. Rinse thoroughly and air dry or towel dry with a lint-free cloth. Inspect seals and fittings for wear and replace if damaged. Clean daily to reduce bacteria, prevent grease buildup, lower energy use, and help pass CSA and health inspections.#@@#Additional Info#@#Micro Matic's CC1301 stainless steel cleaning cup fits G-system flushers, removes residue, offers corrosion resistance, meets CSA standards, and ensures consistent flow and hygiene for high-volume beverage service.#@@#General Info#@#Description #@#

Stop wasting time on temporary solutions. This stainless steel cleaning cup for flusher series installs quickly and performs reliably in high-use bar and kitchen environments, delivering consistent cleaning action for draft tap systems. Operators gain repeatable sanitation results and rapid turnaround during peak service with a compact, serviceable design.

#@@# Stainless Construction#@#

Stainless steel construction resists corrosion and withstands repeated contact with cleaning chemicals and hot water. Technicians will appreciate the durable finish that reduces replacement frequency and maintains sanitary contact surfaces.

#@@# Brass Interface#@#

Brass connector components provide reliable mechanical strength where threads and fittings engage, ensuring consistent seal integrity during flushing cycles. Maintenance crews will notice fewer leaks and reduced downtime for repairs.

#@@# G System Compatibility#@#

Designed for G system applications, this cleaning cup integrates seamlessly with common flusher setups used in commercial tap lines. Installers will complete hookups faster when parts match legacy plumbing and draft cleaning protocols.

#@@# Compact Footprint#@#

Compact dimensions allow mounting in tight service areas behind bars or inside maintenance cabinets without impeding access to lines. Staff will reclaim workspace and simplify routine sanitation without rearranging fixtures.

#@@# Serviceable Design#@#

Removable components allow frontline staff to disassemble and inspect internal passages without specialized tools. Supervisors will reduce service calls and keep equipment in operation through basic on-site maintenance.

#@@# Sanitation Performance#@#

Engineered to direct cleaning solution through faucet internals, the cup aids thorough removal of residue and microbial buildup in draft lines. Quality control teams will document repeatable cleaning cycles that support inventory rotation and public health standards.

#@@#Delivery Details#@#

• Please ensure to handle the product with utmost care.

• Check if the product you have received has all the essential parts and accessories.

• Make sure to examine the product for damage before signing the delivery receipt.

• Contact customer service for delivery concerns.

• Delivery times may vary based on location.#@@#deliverynotes#@#NA#@@#Maintenance Guide#@#Inspect the Micro Matic CC1301 cleaning cup weekly and remove scale with a nonabrasive descaler to preserve stainless steel finish. Rinse thoroughly in potable water and air dry to prevent corrosion. Verify seals and fittings for tight engagement and replace worn components to maintain sanitary operation. Calibrate flow alignment during reassembly to ensure consistent flushing. Document maintenance actions and dates for compliance and asset tracking.