Manufacturing follows industry fabrication practices and the assembly integrates with systems subject to approvals when paired with certified components. Procurement professionals can document compliance pathways when specifying parts for institutional or commercial projects.

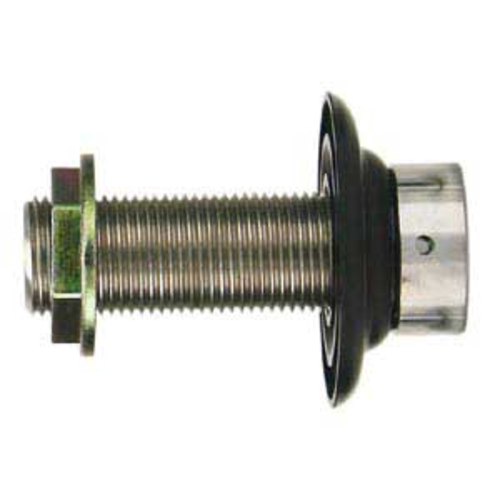

LongDescription#@#NA#@@#Cleaning Instructions#@#Unplug draft lines and relieve keg pressure. Remove faucet shank assembly and soak in warm water with mild detergent for 10–15 minutes. Scrub with a soft brush, flush bore and fittings with potable water, and inspect seals for wear. Sanitize with a food-safe solution per CSA or local guideline, air dry, and reinstall. Clean assemblies weekly; grease buildup increases contamination and equipment stress, raising fire and breakdown risks.#@@#Additional Info#@#Micro Matic 4333A-516 faucet shank assembly features a 3.13" body with a 0.31" bore for secure draft beer connections, CNC-machined brass, and CSA-compliant materials; technicians install and service lines reliably for commercial beverage systems.#@@#General Info#@#Description #@#

Manufacturing follows industry fabrication practices and the assembly integrates with systems subject to approvals when paired with certified components. Procurement professionals can document compliance pathways when specifying parts for institutional or commercial projects.#@@#Delivery Details#@#

• Please ensure to handle the product with utmost care.

• Check if the product you have received has all the essential parts and accessories.

• Make sure to examine the product for damage before signing the delivery receipt.

• Contact customer service for delivery concerns.

• Delivery times may vary based on location.#@@#deliverynotes#@#NA#@@#Maintenance Guide#@#Inspect the Micro Matic 4333A-516 shank assembly weekly for corrosion and secure fittings. Remove faucet and flush lines with warm water and approved brewery cleaner; circulate per manufacturer concentration to remove biofilm. Lubricate seals with food-grade lubricant during reassembly and torque fittings to specified values. Verify alignment and replace rubber gaskets at first sign of wear. Record maintenance steps and intervals for CSA compliance.