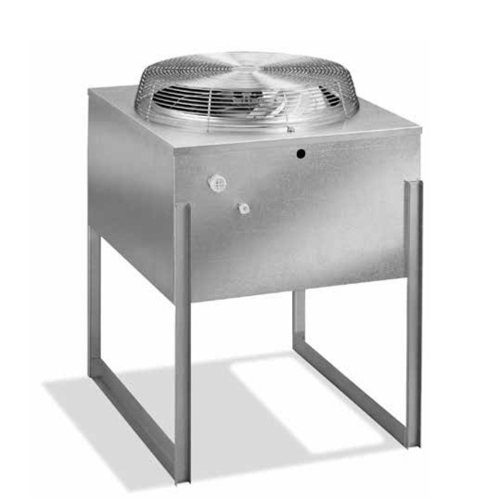

The Manitowoc JCT1200Q is a remote air-cooled condensing unit designed for KDT-1000N and KYT-1000N ice machines. Featuring a corrosion-resistant coated coil, this unit is ideal for coastal environments, providing superior durability and efficient cooling performance.

LongDescription#@#NA#@@#Cleaning Instructions#@#Regularly clean the exterior with a damp cloth to remove debris and salt buildup. Inspect and clean the condenser coil every six months to maintain optimal airflow. Ensure the unit remains unobstructed for efficient cooling performance.#@@#Additional Info#@#The JCT1200Q is a high-performance, air-cooled remote condensing unit featuring a corrosion-resistant coated coil. Ideal for coastal installations, it ensures long-lasting durability in harsh environments.#@@#General Info#@#Description #@#

The Manitowoc JCT1200Q is a remote air-cooled condensing unit designed for KDT-1000N and KYT-1000N ice machines. Featuring a corrosion-resistant coated coil, this unit is ideal for coastal environments, providing superior durability and efficient cooling performance.

#@@# Coastal-Ready Construction #@#

Equipped with a coated coil for enhanced corrosion protection, this unit is ideal for installations within five miles of coastal areas, ensuring long-term reliability.

#@@# Vertical Discharge Design #@#

The vertical discharge configuration improves airflow efficiency, helping maintain consistent performance in commercial applications.

#@@# Remote Air-Cooled System #@#

Designed for remote installation, this air-cooled unit reduces noise and heat in indoor spaces while maintaining efficient ice machine operation.

#@@# High-Capacity Cooling #@#

Optimized for Manitowoc’s KDT-1000N and KYT-1000N models, this condensing unit supports high-volume ice production with stable temperature control.

#@@# AHRI & UL Certified #@#

This unit meets AHRI, UL, and CE standards, ensuring compliance with industry regulations for safety and performance.

#@@# Ideal for Commercial Use #@#

Perfect for restaurants, hotels, and coastal food service operations, the Manitowoc JCT1200Q ensures reliable ice machine cooling even in demanding environments.#@@#Delivery Details#@#• Ships via freight carrier

• Requires a commercial delivery address

• Liftgate service available upon request

• Signature required upon delivery

• Inspect for damage before signing#@@#deliverynotes#@#Report any damages within 48 hours for a smooth claims process.#@@#Maintenance Guide#@#Inspect and clean the condenser coil at least twice a year to prevent corrosion and maintain efficiency. Ensure proper airflow around the unit and remove any debris buildup for optimal cooling performance.