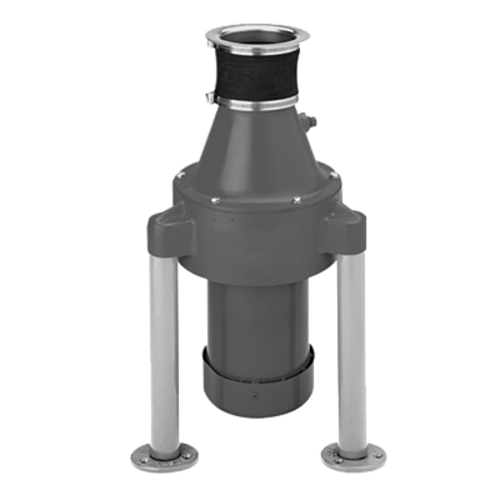

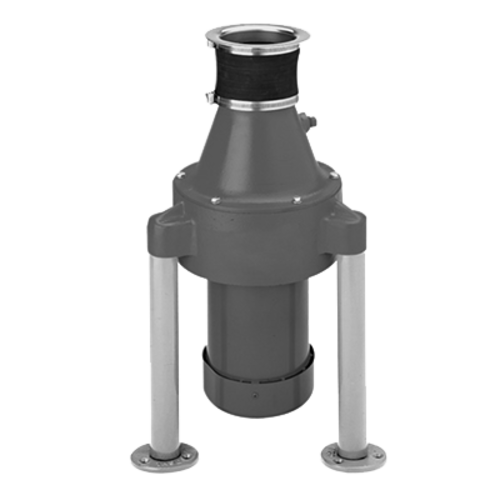

Stop trading uptime for power. This industrial disposer combines robust motor torque and durable cast iron housing to clear heavy organic waste quickly while preserving system reliability. Facility managers and kitchen operators will gain consistent grind performance and simplified serviceability in high-throughput environments.

LongDescription#@#NA#@@#Cleaning Instructions#@#Unplug unit and lock out power. Remove feed and clean rotor chamber with a nylon brush and mild detergent; rinse with warm water. Inspect cast iron housing and clamps for corrosion; tighten clamps as needed. Clear vents and check 208/230v connections; verify 1-Ph wiring before reconnecting. Degrease exterior and dry thoroughly. Perform monthly coil and seal checks to prevent fires, reduce breakdowns, lower energy use and ensure CSA compliance.#@@#Additional Info#@#Insinger N-150L-1 disposer has a cast alloy body, 1-1/2 HP motor, and 8" rotor for 208/230v, 1-Ph service. It includes a connector sleeve, clamps, weighs 120 pounds, and is built for continuous commercial kitchen waste grinding.#@@#General Info#@#Description #@#

Stop trading uptime for power. This industrial disposer combines robust motor torque and durable cast iron housing to clear heavy organic waste quickly while preserving system reliability. Facility managers and kitchen operators will gain consistent grind performance and simplified serviceability in high-throughput environments.

#@@# Power Delivery#@#

The unit uses a 1-1/2 HP motor rated for 208/230 volts in single-phase configuration, providing high torque for continuous grinding of dense waste. Engineers will appreciate the electrical compatibility with standard commercial lines and the capacity to handle peak load conditions without stalling.

#@@# Heavy-Duty Construction#@#

Cast iron housing offers structural rigidity and thermal mass that reduce vibration and extend service intervals under repetitive use. Maintenance teams will note the corrosion resistance and impact tolerance that sustain alignment and seal integrity over time.

#@@# Rotor Design#@#

An 8-inch rotor provides a large grinding surface area and balanced rotation to process food solids efficiently. Kitchens will experience fewer clog incidents and more predictable flow into downstream plumbing when operators follow recommended feed rates.

#@@# Compact Footprint#@#

The disposer keeps installation space minimal while delivering industrial performance, enabling placement under sinks or in compact service stations. Planners can integrate the unit into crowded back-of-house layouts without sacrificing access for routine inspection.

#@@# Service Access#@#

The delivery includes a basic unit with a connector sleeve and clamps to simplify field attachment and reduce install time. Technicians will benefit from straightforward mechanical interfaces that limit labor during replacement or seasonal maintenance.

#@@# Application Versatility#@#

The product suits commercial operations such as hospitals, universities, cafeterias, and bars where high-volume waste processing protects drains and reduces manual handling.

#@@#Delivery Details#@#

• Please ensure to handle the product with utmost care.

• Check if the product you have received has all the essential parts and accessories.

• Make sure to examine the product for damage before signing the delivery receipt.

• Contact customer service for delivery concerns.

• Delivery times may vary based on location.#@@#deliverynotes#@#NA#@@#Maintenance Guide#@#Inspect the Insinger N-150L-1 disposer weekly for reliable operation and reduced downtime. Remove power before servicing. Clean the rotor chamber with warm water and a mild, food-safe detergent; briefly operate the unit while introducing water to remove debris. Check mounting bolts and clamps for tightness per manufacturer specs. Verify electrical connections at 208/230 volts and ensure 1-Ph power; replace frayed leads. Lubricate seals quarterly with a silicone-based food-grade lubricant.