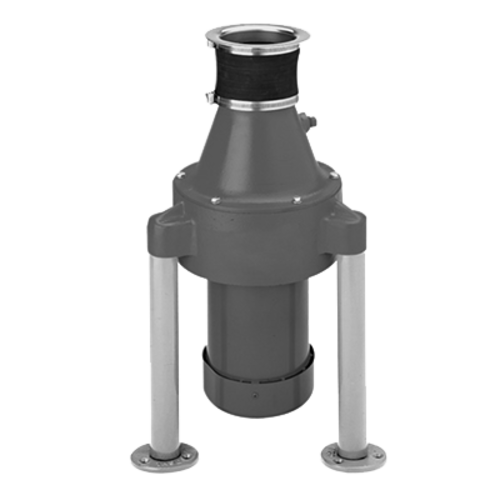

This industrial disposer is designed to deliver consistent grind performance and rugged construction to handle commercial dishroom demands while maintaining efficient power use and serviceability. It provides a stable, high-capacity solution for kitchens, cafeterias, and institutions that process high organic loads.

LongDescription#@#NA#@@#Cleaning Instructions#@#Unplug power and lock out the circuit before servicing. Remove splash guard and debris; flush throat with warm water. Scrub cast iron housing and 6" rotor using a mild detergent and non-abrasive pad. Rinse thoroughly and dry to prevent corrosion. Inspect mounting bolts and gasket; torque to spec and replace damaged seals. Clean vents and surrounding areas to remove grease and reduce fire risk. Record cleaning date and findings for CSA and inspection compliance.#@@#Additional Info#@#Insinger I-125L-3 Disposer features a 1 HP motor, 4-1/2" throat, and 6" rotor for commercial kitchens. It operates on 208/220 volts, 3.8 amps, 3-Ph power, with a durable cast iron body and splash guard gasket.#@@#General Info#@#Description #@#

This industrial disposer is designed to deliver consistent grind performance and rugged construction to handle commercial dishroom demands while maintaining efficient power use and serviceability. It provides a stable, high-capacity solution for kitchens, cafeterias, and institutions that process high organic loads.

Engineers built the unit to resist impact and minimize vibration during extended runs. Operators will note the sustained structural integrity and reduced noise transmission compared with lighter materials.

A 1 horsepower motor provides reliable torque for continuous grinding of food waste in high-volume settings. Technicians can expect stable amperage draw at 3.8 amps on 208/220 volts three-phase power, supporting predictable electrical planning.

The 4-1/2 inch throat accepts large volumes of solids, reducing jam incidents and speeding throughput during peak service hours. Crew members will experience fewer stoppages and faster cycle recovery.

A 6 inch rotor offers broad contact area for accelerated maceration and consistent particle reduction. Maintenance staff will benefit from reduced wear rates and longer intervals between service events.

The unit ships with six mounting bolts without heads to simplify field installation and allow secure anchoring to existing dishroom mounts. Installers can align and secure the disposer quickly while maintaining a low profile connection.

Manufacturers include a splash guard gasket for leak prevention at the discharge interface and recommend contacting factory for replacement rotor pricing. Facility managers receive clear parts pathways and can plan lifecycle costs with greater certainty.

#@@#Delivery Details#@#

• Please ensure to handle the product with utmost care.

• Check if the product you have received has all the essential parts and accessories.

• Make sure to examine the product for damage before signing the delivery receipt.

• Contact customer service for delivery concerns.

• Delivery times may vary based on location.#@@#deliverynotes#@#NA#@@#Maintenance Guide#@#Inspect mounting bolts, inlet flange, and splash guard gasket weekly to prevent leaks. Lubricate the motor shaft per the manufacturer’s schedule using specified greases to maintain torque. Verify electrical connections at 208/220 volts, 3.8 amps, 60 hertz, 3-Ph to avoid overheating; tighten terminals and replace scorched wiring. Clean rotor and throat with a nonabrasive brush; flush with warm water after each shift. Replace the gasket when hardening appears.