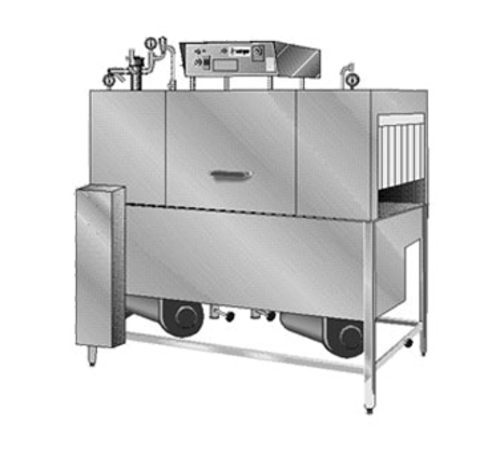

Stop compromising cycle time for sanitation. This conveyor dishwasher delivers continuous, high-temperature cleaning at a commercial pace, engineered to move large volumes through a single-tank system with integrated prewash and power wash stages. Food service operators maintain consistent wash quality while sustaining throughput that matches busy kitchens and catering operations.

LongDescription#@#NA#@@#Cleaning Instructions#@#Unplug power and allow unit to cool. Remove racks and wash debris from conveyor, prewash, and wash sections with a brush and mild detergent. Flush tank and clean filters; drain and rinse. Scrub door gaskets and exterior stainless steel with non-abrasive cleaner. Clean spray arms and nozzles; clear clogs. Sanitize high-temp surfaces per CSA guidelines. Inspect coils and vents; remove grease to prevent fires. Dry all parts before restarting power.#@@#Additional Info#@#Insinger ADMIRAL 66 conveyor dishwasher delivers 233 racks/hour at 208 volts, 3-phase, with a high-temperature tank, prewash, electric heat, stainless steel, CrossFire wash system, and 17,500 watts for continuous foodservice.#@@#General Info#@#Description #@#

Stop compromising cycle time for sanitation. This conveyor dishwasher delivers continuous, high-temperature cleaning at a commercial pace, engineered to move large volumes through a single-tank system with integrated prewash and power wash stages. Food service operators maintain consistent wash quality while sustaining throughput that matches busy kitchens and catering operations.

#@@# Capacity Throughput#@#

Insinger specifies approximately 233 racks per hour, enabling steady processing that suits cafeterias, hospitals, and high-volume restaurants. Facility managers achieve predictable shift planning because rack counts align with operational demand.

#@@# High-Temperature Cleaning#@#

Engineered for high-temp operation without a booster, the system generates sanitizing rinse temperatures using electric tank heat or an optional steam injector configuration. Safety teams receive chemical reduction benefits while compliance officers see consistent sanitizing performance.

#@@# CrossFlow Wash System#@#

The CrossFire wash architecture targets uniform wash coverage across each rack to reduce rewash events. Kitchen supervisors observe lower labor time per rack and fewer service interruptions due to improved soil removal.

#@@# Stainless Construction#@#

Built with a stainless steel frame, legs, and feet, the unit resists corrosion and stands up to daily cleaning protocols common in institutional settings. Maintenance teams experience easier surface care and longer service life for housing components.

#@@# Single Tank With Prewash#@#

The single-tank layout integrates a prewash section and power wash stage to strip heavy soils before the final rinse, reducing blockage risk and preserving wash pump performance. Engineering staff benefit from simplified plumbing and fewer leak points compared with multi-tank designs.

#@@#Delivery Details#@#

• Please ensure to handle the product with utmost care.

• Check if the product you have received has all the essential parts and accessories.

• Make sure to examine the product for damage before signing the delivery receipt.

• Contact customer service for delivery concerns.

• Delivery times may vary based on location.#@@#deliverynotes#@#NA#@@#Maintenance Guide#@#Inspect spray nozzles and remove scale weekly to maintain consistent rinse coverage. Calibrate rinse temperature and verify final rinse exceeds 180°F for sanitization. Flush drain screens daily and inspect pump seals for wear; replace seals showing cracks. Clean conveyor chain and lubricate pivot points with food‑grade lubricant monthly. Descale tank interior with manufacturer‑approved solution quarterly. Verify electrical connections and 208v 3‑Ph supply before operation.